Types of Piezoelectric Actuators:

- Piezoelectric Actuators:

Piezoelectric actuators employ the piezoelectric effect to generate motion when subjected to an electric field. They are known for their high precision and responsiveness, making them suitable for micro-manipulation tasks in fields like biomedical robotics and nanotechnology. Piezoelectric actuators operate on the principle of the piezoelectric effect, which describes the phenomenon where certain materials produce an electric charge in response to mechanical stress or deformation. Piezoelectric materials, such as lead zirconate titanate (PZT) ceramics or certain types of crystals, possess this unique property, making them ideal candidates for actuation in robotics applications.

When an electric voltage is applied to a piezoelectric material, it undergoes deformation or displacement, generating mechanical motion. Conversely, when mechanical force is applied to the material, it generates an electric charge. This bidirectional coupling between electrical and mechanical energy allows piezoelectric actuators to convert electrical signals into precise mechanical motion and vice versa.

Types of Piezoelectric Actuators:

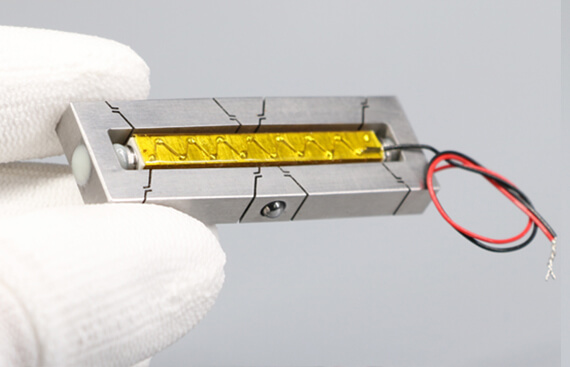

- Piezoelectric Stack Actuators:

Piezoelectric stack actuators are among the most common types of piezoelectric actuators, consisting of multiple layers of piezoelectric material sandwiched between electrodes. When an electric field is applied across the stack, the piezoelectric layers expand or contract, generating mechanical displacement along the axis of the stack. These actuators offer high precision and displacement capabilities, making them ideal for applications requiring nanoscale positioning and fine motion control, such as scanning probe microscopy and optical alignment systems.

Piezoelectric Stack Actuators: Precision in Motion

In the realm of robotics, where precision and control are paramount, piezoelectric stack actuators emerge as fundamental components driving intricate motion with unparalleled accuracy. Leveraging the piezoelectric effect, these advanced devices translate electrical energy into precise mechanical motion, enabling robots to perform delicate tasks with remarkable finesse. Join us on an in-depth exploration of piezoelectric stack actuators, unraveling their principles, functionalities, and transformative role in shaping the landscape of modern robotics.

Principles of Piezoelectric Stack Actuators:

Piezoelectric stack actuators operate on the principle of the piezoelectric effect, a phenomenon exhibited by certain materials such as lead zirconate titanate (PZT) ceramics or certain crystals. When subjected to an electric field, these materials undergo mechanical deformation or displacement, and conversely, when subjected to mechanical stress, they generate an electric charge. This bidirectional coupling between electrical and mechanical energy forms the basis of piezoelectric actuation.

Piezoelectric stack actuators consist of multiple layers of piezoelectric material bonded together, with electrodes applied to the top and bottom surfaces. When a voltage is applied across the stack, an electric field is generated, causing the layers to expand or contract in a coordinated manner. This results in a cumulative displacement along the axis of the stack, producing linear motion. By controlling the magnitude and polarity of the applied voltage, precise control over the displacement of the stack actuator can be achieved.

Functionalities of Piezoelectric Stack Actuators:

High Precision Motion:

Piezoelectric stack actuators offer exceptional precision motion control, allowing robots to perform tasks with sub-micron accuracy and repeatability. The inherent stiffness and responsiveness of piezoelectric materials enable precise positioning and fine adjustments, making stack actuators ideal for applications such as nanomanipulation, microscopy, and semiconductor manufacturing.

Fast Response Times:

Piezoelectric stack actuators exhibit rapid response times, with instantaneous actuation and minimal lag between input signals and motion output. The direct conversion of electrical energy into mechanical motion enables stack actuators to achieve high-frequency vibrations and rapid displacement, making them suitable for applications requiring dynamic motion control and high-speed operation in robotics.

High Force Output:

Despite their compact size, piezoelectric stack actuators offer high force output, allowing robots to exert significant pushing or pulling forces. The stacked configuration of multiple piezoelectric layers enables stack actuators to generate substantial mechanical displacement under applied voltage, providing the necessary force for tasks such as actuating valves, gripping objects, and applying pressure in material testing.

Non-Magnetic and Non-Conductive Properties:

Piezoelectric stack actuators exhibit non-magnetic and non-conductive properties, making them suitable for use in environments where electromagnetic interference (EMI) must be minimized. The absence of magnetic fields and electrical conductivity ensures compatibility with medical devices, scientific instruments, and electronics in robotics applications, particularly in sensitive environments such as magnetic resonance imaging (MRI) or electron microscopy.

Compact and Lightweight Design:

Piezoelectric stack actuators feature compact and lightweight designs, minimizing space requirements and enabling easy integration into robotic systems. The thin and flexible nature of piezoelectric materials allows for miniaturization and precise positioning of stack actuators in confined spaces, making them suitable for applications such as micro-robotics, biomedical devices, and adaptive optics.

Significance of Piezoelectric Stack Actuators in Robotics:

Precision and Accuracy:

Piezoelectric stack actuators play a crucial role in enhancing the precision and accuracy of robotic systems, enabling them to perform tasks with sub-micron resolution and repeatability. Whether positioning optical components in laser systems, manipulating micro-scale objects in biomedical applications, or aligning components in semiconductor manufacturing, stack actuators offer unparalleled precision motion control for a wide range of robotics applications.

Dynamic and Responsive Motion:

Piezoelectric stack actuators contribute to the dynamic and responsive motion of robots, allowing them to execute rapid and precise movements with agility and efficiency. The fast response times and high-force output of stack actuators enable robots to perform dynamic tasks such as vibration control, high-speed scanning, and rapid positioning in robotics applications.

Versatility and Adaptability:

Piezoelectric stack actuators provide versatility and adaptability in robotics applications, offering customizable motion profiles and flexible integration options. Whether driving linear motion, generating complex vibration patterns, or applying precise forces, stack actuators can be tailored to specific task requirements, making them suitable for a wide range of industries and applications in robotics.

Miniaturization and Integration:

Piezoelectric stack actuators enable miniaturization and integration of robotic systems, allowing for compact and lightweight designs with precise motion capabilities. The stacked configuration of multiple piezoelectric layers enables actuators to generate substantial forces and displacements while occupying minimal space, making them suitable for portable devices, wearable technology, and micro-robotic systems.

Innovation and Advancement:

Ongoing research and development in piezoelectric stack actuator technologies drive innovation and advancement in the field of robotics, unlocking new possibilities for performance, efficiency, and functionality. From advancements in material science and manufacturing techniques to innovations in control algorithms and system integration, stack actuators continue to evolve, enabling robots to push the boundaries of precision, speed, and versatility.

In conclusion, piezoelectric stack actuators stand as essential components in the realm of robotics, offering precision motion capabilities, responsiveness, and versatility for a wide range of applications and industries. From microscopic manipulations in biomedical research to high-speed scanning in industrial automation, stack actuators empower robots to excel in tasks requiring precision, agility, and dynamic motion control. As robotics technology continues to advance and evolve, the significance of piezoelectric stack actuators as drivers of innovation and progress remains steadfast, shaping the future of automation and human-machine interaction.

- Piezoelectric Tube Actuators:

Piezoelectric tube actuators utilize the radial expansion or contraction of a cylindrical piezoelectric tube to generate linear motion. By applying an electric field to the inner or outer surface of the tube, the piezoelectric material expands or contracts, causing the tube to elongate or contract along its axis. Piezoelectric tube actuators offer high force output and displacement, making them suitable for applications such as microfluidics, valve control, and precision machining, where linear motion and force are critical for task execution.

- Piezoelectric Benders and Flexures:

Piezoelectric benders and flexures utilize the bending or flexing motion of piezoelectric elements to generate mechanical displacement. These actuators consist of thin piezoelectric strips or beams bonded to a flexible substrate, allowing them to bend or flex in response to an applied electric field. Piezoelectric benders and flexures offer high speed and precision, making them suitable for applications such as adaptive optics, active vibration damping, and micro-robotics, where rapid response and precise control are essential for performance.

- Piezoelectric Resonators:

Piezoelectric resonators leverage the resonance phenomenon of piezoelectric materials to generate mechanical vibration or oscillation. These actuators consist of piezoelectric elements bonded to a resonant structure, such as a cantilever or tuning fork, which vibrates at a specific frequency when subjected to an electric field. Piezoelectric resonators find applications in areas such as ultrasonic cleaning, ultrasonic welding, and acoustic wave devices, where mechanical vibration or oscillation is utilized for material processing, sensing, or actuation.

- Piezoelectric Motors:

Piezoelectric motors utilize the piezoelectric effect to drive rotational or linear motion without the need for traditional mechanical components such as gears or bearings. These motors operate by inducing frictional or contact forces between piezoelectric elements and a moving platform, causing it to translate or rotate with high precision and resolution. Piezoelectric motors are used in applications such as precision optics, micro-positioning stages, and nanopositioning systems, where compact size, low inertia, and precise motion control are required.

Functionalities of Piezoelectric Actuators:

- Precision Positioning:

Piezoelectric actuators offer unparalleled precision in positioning, enabling robots to achieve sub-micron and nanometer-level accuracy in motion control. The inherent stiffness and responsiveness of piezoelectric materials allow for rapid and precise displacement, making them ideal for applications requiring fine adjustment, alignment, or scanning. Whether performing microscopy, lithography, or optical alignment, piezoelectric actuators provide the precise positioning needed to achieve high-resolution imaging, patterning, and alignment in robotics.

- Fast Response Time:

Piezoelectric actuators exhibit rapid response times, enabling robots to execute dynamic motions and rapid adjustments with minimal delay. The direct coupling between electrical input and mechanical output in piezoelectric materials allows for millisecond-level response times, making them ideal for applications requiring fast actuation, feedback, or modulation. Whether compensating for dynamic disturbances, tracking fast-moving targets, or adjusting for environmental changes, piezoelectric actuators ensure rapid and responsive performance in robotics.

- High Force and Power Density:

Despite their compact size, piezoelectric actuators offer high force and power density, enabling robots to exert significant forces and torques in confined spaces. The electromechanical coupling efficiency of piezoelectric materials allows for efficient energy conversion and transmission, resulting in high force output per unit volume or weight. Whether gripping objects, manipulating tools, or driving mechanisms, piezoelectric actuators provide the high force and power density needed to accomplish tasks with precision and efficiency in robotics.

- Low Power Consumption:

Piezoelectric actuators are known for their low power consumption, making them energy-efficient solutions for robotic systems. The direct conversion of electrical energy into mechanical displacement in piezoelectric materials minimizes energy losses and wasted power, resulting in efficient actuation with minimal heat generation or dissipation. Whether operating in battery-powered devices, portable instruments, or energy-constrained environments, piezoelectric actuators offer low power consumption and prolonged battery life, enhancing the autonomy and sustainability of robotic systems.

- Non-Magnetic and Non-Conductive Properties:

Piezoelectric actuators exhibit non-magnetic and non-conductive properties, making them suitable for use in environments where magnetic interference or electrical conductivity is a concern. Unlike electromagnetic actuators or motors, which may be susceptible to electromagnetic interference (EMI) or magnetic field effects, piezoelectric actuators are immune to magnetic fields and do not generate electromagnetic radiation. This non-magnetic and non-conductive nature makes piezoelectric actuators ideal for applications such as magnetic resonance imaging (MRI), semiconductor manufacturing, and precision instrumentation, where electromagnetic compatibility (EMC) and material purity are critical considerations.

Significance of Piezoelectric Actuators in Robotics:

- Enhanced Precision and Accuracy:

Piezoelectric actuators play a crucial role in enhancing the precision and accuracy of robotic systems, enabling them to perform tasks with sub-micron and nanometer-level resolution. Whether positioning components in semiconductor fabrication, aligning optics in laser systems, or scanning surfaces in microscopy, piezoelectric actuators provide the precise motion control needed to achieve high-resolution imaging, patterning, and manipulation in robotics.

- Dynamic and Responsive Motion:

Piezoelectric actuators enable robots to execute dynamic and responsive motions with rapid adjustments and precise control. The fast response times and high bandwidth of piezoelectric materials allow for real-time modulation and adaptation to changing task requirements or environmental conditions. Whether tracking fast-moving targets, compensating for dynamic disturbances, or adjusting for variations in load or friction, piezoelectric actuators ensure dynamic and responsive performance in robotics.

- Miniaturization and Integration:

Piezoelectric actuators facilitate miniaturization and integration in robotic systems, allowing for compact and lightweight designs with high performance and efficiency. The small size, low weight, and high power density of piezoelectric actuators enable

Functionalities of Actuators:

- Motion Generation:

The primary function of actuators is to generate mechanical motion, enabling robots to move their limbs, joints, or end-effectors to perform tasks. Depending on the type of actuator and its design, motion can be achieved through rotational, linear, or oscillatory movements.

- Force and Torque Generation:

Actuators provide the necessary force and torque required to overcome resistance and manipulate objects in the robot’s environment. The force output of an actuator determines its capability to lift, push, pull, or manipulate objects of varying weights and sizes.

- Control and Feedback:

Actuators are equipped with sensors and feedback mechanisms to ensure precise control of motion and interaction with the environment. Feedback from sensors such as encoders and accelerometers allows the robotic system to monitor the position, velocity, and force exerted by the actuators, enabling closed-loop control for accurate and stable operation.

- Adaptability and Flexibility:

Actuators can be designed to exhibit adaptive and flexible behavior, allowing robots to adjust their movements and interactions based on changes in the environment or task requirements. This adaptability is essential for robots operating in dynamic and unstructured environments where conditions may vary unpredictably.

- Energy Efficiency:

Efficient utilization of energy is crucial for the performance and autonomy of robotic systems. Actuators are designed to minimize energy consumption while maximizing output power, ensuring optimal efficiency in various operating conditions. Advancements in actuator technologies, such as brushless motors and smart materials, contribute to enhanced energy efficiency in robotics.

Significance of Actuators in Robotics:

- Functionality and Performance:

Actuators are essential for enabling the functionality and performance of robotic systems. They determine the range of motions, speed, accuracy, and payload capacity of robots, influencing their capabilities across different applications and industries.

- Versatility and Adaptability:

The diverse range of actuators available allows robotic designers to select the most suitable type for specific tasks and environments. Whether it’s precise positioning in manufacturing processes or agile locomotion in mobile robots, actuators provide the necessary versatility and adaptability to meet varied requirements.

- Productivity and Efficiency:

Actuators play a crucial role in enhancing productivity and efficiency in industrial automation and manufacturing processes. By automating repetitive tasks and operating with precision and speed, robots equipped with efficient actuators can improve production throughput, quality, and consistency while reducing labor costs and cycle times.

- Safety and Reliability:

Reliable actuation systems are essential for ensuring the safety of robotic operations, particularly in collaborative and human-robot interaction scenarios. Actuators with built-in safety features, such as overload protection and fail-safe mechanisms, contribute to the overall reliability and integrity of robotic systems, minimizing the risk of accidents and malfunctions.

- Innovation and Advancement:

Ongoing research and development in actuator technologies drive innovation and advancement in the field of robotics. From novel materials and manufacturing techniques to advanced control algorithms and integrated sensing systems, advancements in actuators continue to push the boundaries of what robots can achieve, opening up new possibilities for applications in diverse domains.

In conclusion, actuators form the backbone of robotic systems, enabling them to translate electrical signals into mechanical motion and perform a myriad of tasks with precision, efficiency, and versatility. As robotics continues to evolve and expand into new frontiers, the role of actuators remains indispensable in shaping the future of automation, artificial intelligence, and human-machine interaction.