Types of Gaseous and Chemical Sensors:

- Gaseous and Chemical Sensors:

Gaseous and chemical sensors detect the presence and concentration of specific gasses or chemicals in the environment. These sensors are used in applications such as air quality monitoring, gas leak detection, and chemical analysis. Gas sensors enable robots to detect harmful gasses, while chemical sensors provide insights into environmental pollutants or chemical processes.

Gaseous and Chemical Sensors: Enhancing Robotic Perception in Complex Environments

In the dynamic and ever-evolving landscape of robotics, the ability to sense and respond to gaseous and chemical stimuli is essential for navigating and operating in diverse environments. Gaseous and chemical sensors, equipped with advanced sensing technologies, enable robots to detect, analyze, and monitor the presence of various gasses, vapors, and chemical compounds in their surroundings. These sensors play a crucial role in ensuring safety, environmental monitoring, industrial automation, and healthcare applications. Join us as we explore the intricate world of gaseous and chemical sensors, uncovering their principles, functionalities, and transformative impact on robotics.

Principles of Gaseous and Chemical Sensors:

Gaseous and chemical sensors operate on a variety of principles tailored to detect specific gasses or chemical compounds. These principles include:

- Chemiresistive Sensors:

Chemiresistive sensors detect changes in electrical resistance in response to exposure to specific gasses or vapors. They typically consist of a sensing material, such as metal oxides or conductive polymers, whose electrical conductivity varies when exposed to target gasses due to adsorption or chemical reactions. By measuring the resistance change, chemiresistive sensors can identify and quantify the concentration of gasses present in the environment.

Gaseous and Chemical Sensors: Elevating Robotic Chemiresistive Sensors for Enhanced Sensing

In the burgeoning field of robotics, where precision and adaptability are paramount, chemiresistive sensors stand as a cornerstone technology, facilitating the detection and analysis of various gasses and chemical compounds. These sensors, operating on the principle of electrical resistance modulation in response to specific gas interactions, play a pivotal role in enhancing robotic perception and decision-making in diverse environments. Join us as we delve into the intricacies of chemiresistive sensors, exploring their principles, functionalities, and transformative impact on robotics, particularly in the realm of gaseous and chemical sensing.

- Principles of Chemiresistive Sensors:

Chemiresistive sensors operate based on the principle of electrical resistance variation when exposed to specific gasses or vapors. These sensors typically consist of a sensing material, such as metal oxides or conductive polymers, whose electrical conductivity changes upon interaction with target gasses. When gas molecules adsorb onto the surface of the sensing material, they alter its conductivity, leading to a measurable change in electrical resistance. This change in resistance can be correlated with the concentration of the target gas, enabling precise and selective gas detection.

The sensing mechanism of chemiresistive sensors relies on the interactions between gas molecules and the surface of the sensing material. Depending on the specific gas-surface interactions, chemiresistive sensors can exhibit different sensitivity, selectivity, and response times to various gasses. By carefully selecting the sensing material and optimizing sensor design parameters, chemiresistive sensors can be tailored to detect specific gasses or chemical compounds with high accuracy and reliability.

Functionalities of Chemiresistive Sensors in Robotics:

Chemiresistive sensors provide robots with critical functionalities that enhance their sensing capabilities and enable them to operate effectively in complex environments:

- Gas Detection and Identification:

Chemiresistive sensors enable robots to detect and identify a wide range of gasses and chemical compounds present in the environment. By selectively responding to specific gas molecules, chemiresistive sensors can distinguish between different gasses and provide real-time feedback on their concentrations. This capability is essential for gas leak detection, environmental monitoring, and safety assurance in industrial, commercial, and residential settings.

- Environmental Monitoring and Control:

Chemiresistive sensors support environmental monitoring and control applications by providing robots with the ability to assess air quality, detect pollutant emissions, and monitor chemical processes. By continuously monitoring gas concentrations in the surrounding environment, sensors help robots evaluate environmental impact, track pollution sources, and implement control measures to mitigate risks to human health and the ecosystem.

- Industrial Automation and Safety:

Chemiresistive sensors play a crucial role in industrial automation and safety applications, such as leak detection, process control, and workplace safety monitoring. By detecting gas leaks, spills, or abnormal concentrations in industrial facilities, sensors help optimize production processes, ensure worker safety, and prevent accidents or environmental incidents. Chemiresistive sensors are widely used in industries such as oil and gas, chemical manufacturing, and semiconductor fabrication.

- Healthcare and Medical Diagnostics:

Chemiresistive sensors support healthcare and medical diagnostics by enabling non-invasive monitoring of physiological parameters and metabolic gasses. By detecting biomarkers and volatile organic compounds (VOCs) in breath samples, sensors can aid in the diagnosis and management of respiratory diseases, metabolic disorders, and infectious illnesses. Chemiresistive sensors are increasingly being integrated into medical devices and diagnostic tools for point-of-care testing and personalized healthcare.

- Smart Home and IoT Applications:

Chemiresistive sensors are finding applications in smart home and Internet of Things (IoT) devices for indoor air quality monitoring, gas leak detection, and home automation. By integrating sensors into smart appliances, HVAC systems, and security devices, homeowners can monitor air quality, detect gas leaks, and control indoor environments remotely. Chemiresistive sensors contribute to energy efficiency, safety, and comfort in residential buildings and smart cities.

Advancements and Future Directions:

Recent advancements in chemiresistive sensor technology have focused on improving sensitivity, selectivity, and response times through material engineering, sensor design optimization, and signal processing techniques. Emerging trends include the development of nanomaterial-based sensors, wearable sensor arrays, and miniaturized sensor platforms for portable and distributed sensing applications. Additionally, the integration of chemiresistive sensors with artificial intelligence (AI) algorithms and wireless communication technologies enables real-time data analysis, predictive modeling, and remote monitoring capabilities in robotic systems.

As robotics technology continues to evolve and expand, the integration of advanced chemiresistive sensors will play a crucial role in enhancing robotic perception, autonomy, and decision-making capabilities. From industrial automation and environmental monitoring to healthcare and smart home applications, chemiresistive sensors offer a versatile and reliable solution for gas and chemical sensing in robotics. By leveraging the unique capabilities of chemiresistive sensors, robots can navigate complex environments, respond to changing conditions, and fulfill a wide range of tasks with precision and efficiency.

- Electrochemical Sensors:

Electrochemical sensors utilize electrochemical reactions to detect and quantify target gases or chemical species. They comprise electrodes immersed in an electrolyte solution, with one electrode acting as the sensing element and the other as the reference. When target gases come into contact with the sensing electrode, they undergo specific redox reactions, leading to changes in the electrical current or potential, which can be correlated with the gas concentration.

Gaseous and Chemical Sensors: Advancing Robotic Capabilities through Electrochemical Sensing

In the intricate realm of robotics, where precision, adaptability, and safety are paramount, electrochemical sensors emerge as indispensable components, providing unparalleled capabilities for gaseous and chemical detection. Operating on the principles of electrochemical reactions, these sensors offer exceptional sensitivity, selectivity, and reliability, enabling robots to perceive, analyze, and respond to a wide range of gasses and chemical compounds in their surroundings. Join us as we explore the profound impact of electrochemical sensors on robotics, uncovering their principles, functionalities, and transformative role in enhancing robotic perception and decision-making.

Principles of Electrochemical Sensors:

Electrochemical sensors operate based on the principle of electrochemical reactions occurring at the sensor-electrolyte interface in response to the presence of specific gasses or chemical species. These sensors typically consist of electrodes immersed in an electrolyte solution, with one electrode acting as the sensing element and the other as the reference. When target gasses or chemical compounds come into contact with the sensing electrode, they undergo specific redox (oxidation-reduction) reactions, leading to changes in the electrical current or potential at the electrode interface.

The magnitude of the electrical signal generated by the electrochemical reactions is directly proportional to the concentration of the target analyte, allowing for quantitative detection and measurement. Electrochemical sensors can be classified into different types based on the specific electrochemical reactions involved, including amperometric, potentiometric, and conductometric sensors. Each type offers unique advantages in terms of sensitivity, selectivity, response time, and suitability for different applications.

Functionalities of Electrochemical Sensors in Robotics:

Electrochemical sensors provide robots with critical functionalities that enhance their sensing capabilities and enable them to operate effectively in complex environments:

- Gas Detection and Identification:

Electrochemical sensors enable robots to detect and identify a wide range of gasses and chemical compounds with high sensitivity and selectivity. By selectively responding to specific analytes, such as toxic gasses, volatile organic compounds (VOCs), or electroactive species, electrochemical sensors can distinguish between different gasses and provide real-time feedback on their concentrations. This capability is essential for applications such as industrial safety, environmental monitoring, and air quality assessment.

- Environmental Monitoring and Control:

Electrochemical sensors support environmental monitoring and control by enabling robots to assess air quality, detect pollutant emissions, and monitor chemical processes in real-time. By continuously monitoring gas concentrations in the surrounding environment, sensors help robots evaluate environmental impact, track pollution sources, and implement control measures to mitigate risks to human health and the ecosystem. Electrochemical sensors are widely used in industries such as manufacturing, petrochemicals, and wastewater treatment.

- Industrial Automation and Safety:

Electrochemical sensors play a crucial role in industrial automation and safety applications, such as leak detection, process monitoring, and occupational health monitoring. By detecting gas leaks, spills, or abnormal concentrations in industrial facilities, sensors help optimize production processes, ensure worker safety, and prevent accidents or environmental incidents. Electrochemical sensors are commonly used in industries such as oil and gas, chemical manufacturing, and semiconductor fabrication.

- Healthcare and Medical Diagnostics:

Electrochemical sensors support healthcare and medical diagnostics by enabling non-invasive monitoring of physiological parameters and metabolic gasses. By detecting biomarkers and electroactive species in bodily fluids or breath samples, sensors can aid in the diagnosis and management of respiratory diseases, metabolic disorders, and infectious illnesses. Electrochemical sensors are increasingly being integrated into medical devices and diagnostic tools for point-of-care testing and personalized healthcare.

- Consumer Electronics and IoT Applications:

Electrochemical sensors are finding applications in consumer electronics and Internet of Things (IoT) devices for indoor air quality monitoring, gas detection, and personal safety. By integrating sensors into wearable devices, smart home appliances, and personal gadgets, consumers can monitor air quality, detect gas leaks, and receive alerts about potential hazards or health risks. Electrochemical sensors contribute to safety, convenience, and comfort in residential and commercial settings.

Advancements and Future Directions:

Recent advancements in electrochemical sensor technology have focused on improving sensitivity, selectivity, response time, and durability through material innovation, sensor miniaturization, and signal processing techniques. Emerging trends include the development of nanostructured electrode materials, solid-state electrolytes, and microfabricated sensor arrays for enhanced performance and integration into compact, portable devices. Additionally, the integration of electrochemical sensors with wireless communication technologies and cloud-based analytics platforms enables real-time data streaming, remote monitoring, and predictive maintenance capabilities in robotic systems.

As robotics technology continues to advance and evolve, the integration of advanced electrochemical sensors will play a crucial role in enhancing robotic perception, autonomy, and decision-making capabilities. From industrial automation and environmental monitoring to healthcare and consumer electronics applications, electrochemical sensors offer a versatile and reliable solution for gaseous and chemical sensing in robotics. By leveraging the unique capabilities of electrochemical sensors, robots can navigate complex environments, respond to changing conditions, and fulfill a wide range of tasks with precision and efficiency.

- Photoionization Detectors (PID):

PID sensors employ ultraviolet (UV) light to ionize target glasses, generating ionized particles that can be measured electrically. When exposed to UV light, molecules of the target gas absorb photons and become ionized, producing a measurable current or charge. PID sensors are particularly sensitive to volatile organic compounds (VOCs) and are commonly used in industrial hygiene, environmental monitoring, and gas detection applications.

Photoionization Detectors (PIDs): Illuminating Robotics with Advanced Gas Sensing

In the expansive domain of robotics, where precision, safety, and environmental awareness are paramount, Photoionization Detectors (PIDs) shine as indispensable components, providing invaluable capabilities for gas detection and monitoring. These sensors, operating on the principle of photoionization, offer exceptional sensitivity, selectivity, and versatility, enabling robots to detect, quantify, and respond to a wide range of volatile organic compounds (VOCs) and hazardous gasses in diverse environments. Join us as we delve into the intricacies of PIDs, exploring their principles, functionalities, and transformative role in enhancing robotic perception and decision-making.

Principles of Photoionization Detectors:

Photoionization Detectors operate based on the principle of photoionization, wherein gas molecules are ionized upon exposure to ultraviolet (UV) light. These detectors typically consist of a lamp that emits UV radiation, an ionization chamber, and electrodes for measuring the resulting ionization current. When UV light interacts with gas molecules, it ionizes them, creating positively charged ions and free electrons. The ionization current generated by this process is directly proportional to the concentration of target gasses, allowing for quantitative detection and measurement.

One of the key advantages of PIDs is their broad detection range, which spans from low parts-per-billion (ppb) to high parts-per-million (ppm) levels, depending on the specific VOCs or gasses being targeted. Additionally, PIDs offer rapid response times, real-time data output, and minimal interference from other gasses, making them highly effective for on-the-spot gas detection and monitoring in various applications.

Functionalities of Photoionization Detectors in Robotics:

Photoionization Detectors provide robots with critical functionalities that enhance their sensing capabilities and enable them to operate effectively in complex environments:

- VOC and Gas Detection:

PIDs enable robots to detect and quantify a wide range of volatile organic compounds (VOCs) and hazardous gasses with exceptional sensitivity and selectivity. By selectively ionizing target molecules, PIDs can identify and measure concentrations of gasses such as benzene, toluene, xylene, and other organic compounds commonly found in industrial, commercial, and residential environments.

- Environmental Monitoring and Safety:

PIDs support environmental monitoring and safety applications by enabling robots to assess air quality, detect chemical spills, and monitor pollutant emissions in real-time. By continuously monitoring gas concentrations in the surrounding environment, sensors help robots evaluate environmental impact, track pollution sources, and implement control measures to mitigate risks to human health and the ecosystem.

- Industrial Hygiene and Occupational Safety:

PIDs play a crucial role in industrial hygiene and occupational safety applications, such as workplace monitoring, leak detection, and hazard assessment. By detecting VOCs and hazardous gasses in industrial facilities, sensors help ensure worker safety, prevent exposure to toxic chemicals, and comply with regulatory requirements for air quality and occupational health.

- Hazmat and Emergency Response:

PIDs are essential tools for hazardous materials (Hazmat) and emergency response teams, enabling robots to quickly identify and assess chemical hazards in emergency situations. By detecting toxic gasses, flammable vapors, and unknown substances, sensors help guide response efforts, prioritize evacuation routes, and protect first responders and bystanders from exposure to harmful contaminants.

- Indoor Air Quality and Indoor Environmental Quality (IEQ):

PIDs support indoor air quality monitoring and indoor environmental quality assessments in residential, commercial, and institutional buildings. By detecting VOCs from building materials, furnishings, and cleaning products, sensors help identify sources of indoor pollution, assess ventilation effectiveness, and optimize indoor environments for occupant health and comfort.

Advancements and Future Directions:

Recent advancements in PID technology have focused on enhancing sensitivity, selectivity, and portability through miniaturization, improved lamp designs, and advanced signal processing algorithms. Emerging trends include the development of wireless PID systems, wearable PID devices, and multi-sensor arrays for distributed sensing and remote monitoring applications. Additionally, the integration of PIDs with artificial intelligence (AI) algorithms and cloud-based analytics platforms enables real-time data analysis, predictive modeling, and proactive decision-making in robotic systems.

As robotics technology continues to advance and evolve, the integration of advanced PIDs will play a crucial role in enhancing robotic perception, autonomy, and decision-making capabilities. From industrial automation and environmental monitoring to emergency response and public health applications, PIDs offer a versatile and reliable solution for gas detection and monitoring in robotics. By leveraging the unique capabilities of PIDs, robots can navigate complex environments, respond to changing conditions, and fulfill a wide range of tasks with precision and efficiency.

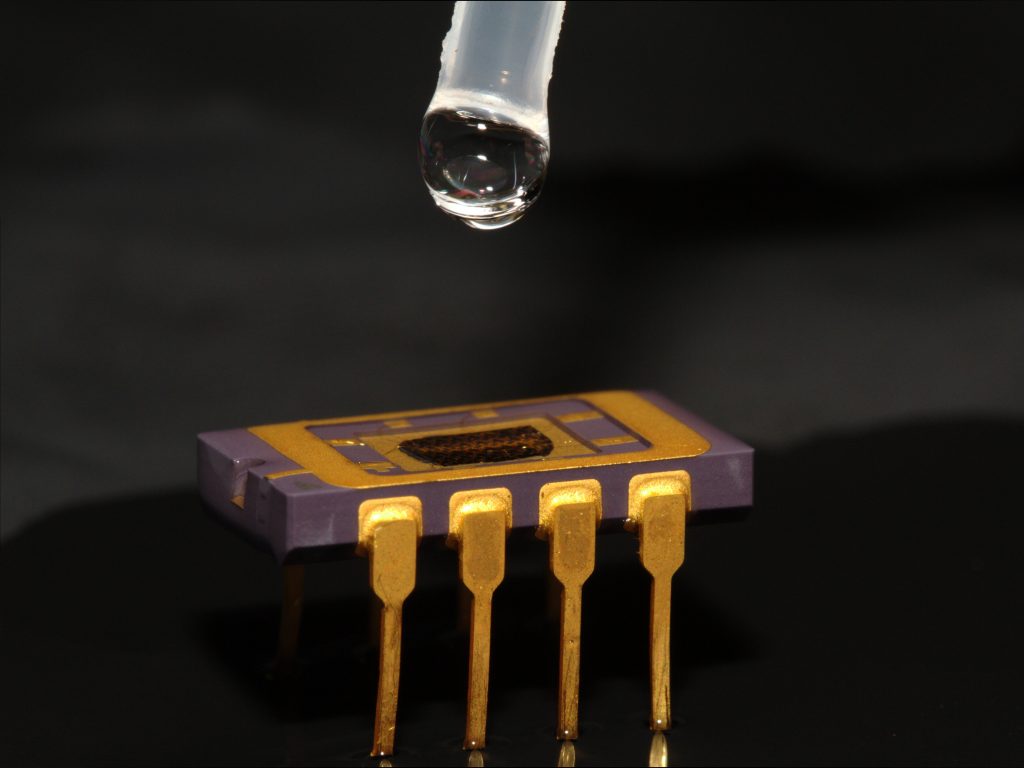

- Metal Oxide Semiconductor (MOS) Sensors:

MOS sensors detect changes in electrical conductivity when exposed to target glasses, based on the adsorption of gas molecules onto the surface of metal oxide films. As gas molecules adsorb onto the sensor surface, they alter the conductivity of the metal oxide layer, resulting in a measurable change in resistance or capacitance. MOS sensors are widely used for gas detection in industrial safety, environmental monitoring, and indoor air quality applications.

- Catalytic Bead Sensors:

Catalytic bead sensors employ catalytic elements, such as platinum or palladium, to promote gas oxidation or reduction reactions in the presence of combustible gasses. When target gasses come into contact with the catalytic surface, they undergo chemical reactions that generate heat, leading to changes in temperature or electrical properties that can be detected by the sensor. Catalytic bead sensors are commonly used for detecting flammable gasses in industrial and safety applications.

Functionalities of Gaseous and Chemical Sensors:

Gaseous and chemical sensors provide robots with critical functionalities that enable them to operate effectively in various environments:

- Gas Detection and Monitoring:

Gaseous and chemical sensors allow robots to detect the presence of hazardous or toxic gasses, such as carbon monoxide, methane, hydrogen sulfide, and volatile organic compounds (VOCs). By continuously monitoring gas concentrations in the environment, sensors help robots identify potential safety hazards, assess air quality, and initiate appropriate response actions to mitigate risks to human health and safety.

- Environmental Monitoring:

Gaseous and chemical sensors enable robots to monitor air quality, pollution levels, and chemical emissions in indoor and outdoor environments. By measuring concentrations of pollutants, greenhouse gasses, and volatile compounds, sensors help assess environmental impact, track pollution sources, and support regulatory compliance efforts in urban, industrial, and residential areas.

- Industrial Automation:

Gaseous and chemical sensors play a crucial role in industrial automation applications, such as process control, leak detection, and emissions monitoring. By detecting leaks, spills, or abnormal gas concentrations in industrial facilities, sensors help optimize production processes, ensure worker safety, and minimize environmental impact, enhancing efficiency and compliance in manufacturing, petrochemical, and automotive industries.

- Healthcare and Medical Monitoring:

Gaseous and chemical sensors support healthcare and medical applications by enabling non-invasive monitoring of physiological parameters, such as exhaled breath analysis, metabolic gas analysis, and anesthesia monitoring. By detecting biomarkers and metabolic gasses in breath samples, sensors help diagnose diseases, monitor patient health, and optimize treatment strategies in clinical and point-of-care settings.

- Environmental Sensing:

Gaseous and chemical sensors enable robots to sense and respond to changes in environmental conditions, such as temperature, humidity, and gas composition. By integrating multiple sensor modalities, including gaseous and chemical sensors, robots can enhance situational awareness, adaptability, and autonomy in outdoor and indoor environments, supporting applications such as environmental monitoring, agriculture, and disaster response.

Significance of Gaseous and Chemical Sensors in Robotics:

Gaseous and chemical sensors play a pivotal role in robotics applications by providing robots with critical capabilities for environmental perception, safety assurance, and decision-making in complex and dynamic environments. From industrial automation and environmental monitoring to healthcare and safety applications, gaseous and chemical sensors contribute to the efficiency, reliability, and adaptability of robotic systems across diverse domains. As robotics technology continues to advance and evolve, the significance of gaseous and chemical sensors in robotics applications will only continue to grow, driving innovation, enabling new capabilities, and shaping the future of automation and robotics.