Types of Pneumatic Actuators:

- Pneumatic Actuators:

Pneumatic actuators utilize compressed air to generate motion. They are lightweight, cost-effective, and ideal for applications requiring rapid movements and moderate force. Pneumatic actuators are commonly used in robotics for tasks such as gripping, lifting, and positioning. In the intricate dance of robotics, where precision meets agility, pneumatic actuators emerge as dynamic components driving seamless motion with remarkable speed and versatility. Utilizing the power of compressed air, these robust devices propel robots through a wide range of tasks across industries, from delicate manipulation in assembly lines to rapid movements in pick-and-place operations. Join us on an extensive exploration of pneumatic actuators, unraveling their types, functionalities, and indispensable role in shaping the landscape of modern robotics.

Types of Pneumatic Actuators:

- Pneumatic Cylinders:

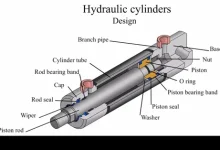

Pneumatic cylinders serve as the backbone of pneumatic actuation systems, converting compressed air into linear motion with remarkable efficiency and speed. These cylinders consist of a piston enclosed within a cylindrical chamber, with compressed air acting upon the piston to generate linear force. Pneumatic cylinders come in various configurations, including single-acting, double-acting, and rotary types, each tailored to specific applications based on factors such as stroke length, load capacity, and speed requirements.

Pneumatic Cylinders: The Workhorses of Dynamic Motion in Robotics

In the intricate world of robotics, where precision, speed, and adaptability are paramount, pneumatic cylinders stand tall as indispensable components driving dynamic motion with remarkable efficiency and versatility. Harnessing the power of compressed air, these robust actuators translate pneumatic energy into linear motion, enabling robots to perform a myriad of tasks across industries, from assembly and material handling to packaging and automotive applications. Let’s embark on an extensive exploration of pneumatic cylinders, unraveling their types, functionalities, and pivotal role in shaping the landscape of modern robotics.

Types of Pneumatic Cylinders:

- Single-Acting Pneumatic Cylinders:

Single-acting pneumatic cylinders are fundamental components in pneumatic systems, converting the energy of compressed air into linear motion in one direction. These cylinders typically consist of a piston connected to a rod, enclosed within a cylindrical chamber. When pressurized air enters the cylinder, it exerts force on one side of the piston, causing it to move in the desired direction. Spring force or an external load then returns the piston to its original position when air pressure is released. Single-acting cylinders are commonly used in applications such as door opening mechanisms, clamping systems, and conveyor actuation.

- Double-Acting Pneumatic Cylinders:

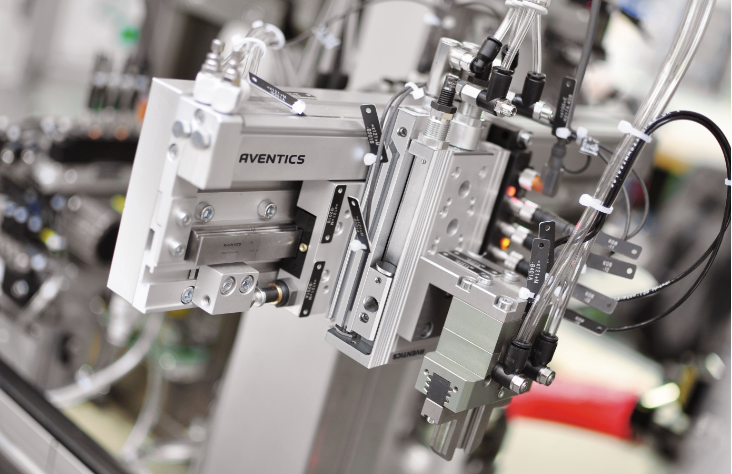

Double-acting pneumatic cylinders provide bidirectional linear motion, offering versatility and control in pneumatic systems. These cylinders feature two ports for air inlet and outlet, allowing compressed air to act on both sides of the piston alternately. As air enters one side of the cylinder, it extends the piston rod, while simultaneously retracting the rod on the opposite side when air is applied to the other port. Double-acting cylinders offer precise control over both extension and retraction strokes, making them suitable for applications such as robotic arms, lifting platforms, and material handling equipment.

- Rodless Pneumatic Cylinders:

Rodless pneumatic cylinders offer compact and space-saving solutions for linear motion applications, particularly in constrained environments or where long stroke lengths are required. These cylinders feature a piston enclosed within a cylindrical chamber, with a magnetically coupled carriage or slider attached to the piston rod. As compressed air enters the cylinder, it drives the piston and carriage assembly along the cylinder’s length, providing linear motion without the need for an external rod. Rodless cylinders are commonly used in applications such as packaging machinery, sliding doors, and gantry systems.

- Compact Pneumatic Cylinders:

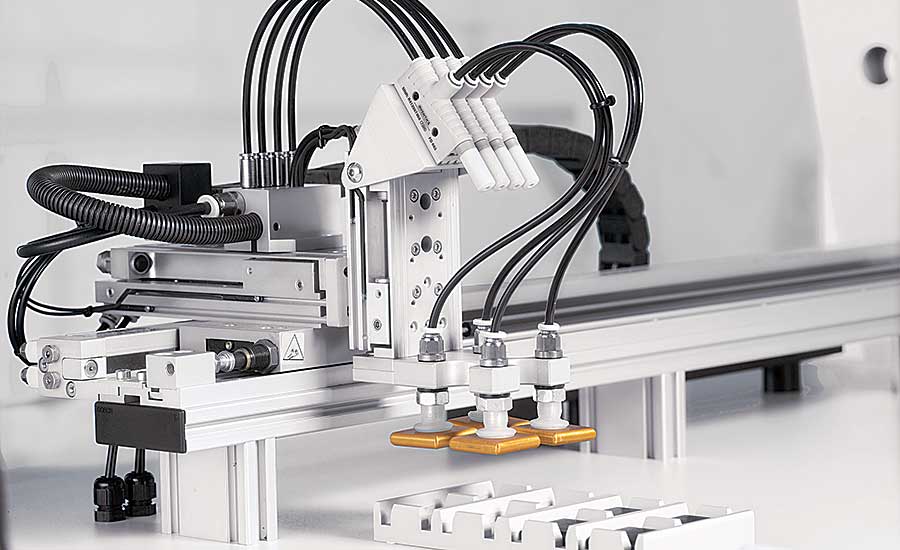

Compact pneumatic cylinders are miniature versions of standard pneumatic cylinders, designed for applications where space is limited or precise motion control is required. These cylinders feature a compact and lightweight design, with reduced overall dimensions and stroke lengths compared to traditional cylinders. Compact cylinders are available in various configurations, including single-acting, double-acting, and guided versions, making them suitable for a wide range of robotics applications such as grippers, indexing mechanisms, and miniature automation systems.

- Tandem Pneumatic Cylinders:

Tandem pneumatic cylinders consist of two or more cylinders connected in series, allowing for increased force output or extended stroke lengths compared to single cylinders. These cylinders feature a common piston rod or carriage assembly shared between multiple cylinders, with air pressure applied sequentially to each cylinder in the tandem arrangement. Tandem cylinders offer enhanced force output and stroke length capabilities, making them suitable for heavy-duty applications such as lifting, pressing, and clamping in robotics and industrial automation.

Functionalities of Pneumatic Cylinders:

- Dynamic Motion:

Pneumatic cylinders excel in delivering dynamic linear motion, enabling robots to perform rapid and precise movements with agility and responsiveness. The instantaneous response of compressed air to control signals allows pneumatic cylinders to achieve high acceleration and deceleration rates, making them ideal for applications requiring fast cycle times, such as pick-and-place operations, sorting systems, and packaging machinery.

- Precise Positioning:

Despite their rapid motion capabilities, pneumatic cylinders offer precise positioning control, enabling robots to achieve accurate and repeatable motion profiles. By modulating air pressure, flow rates, and valve positions, pneumatic systems can regulate the speed and extension/retraction of pneumatic cylinders with precision, ensuring accurate positioning of robotic end effectors, grippers, and other actuated components.

- Simple and Reliable Operation:

Pneumatic cylinders feature a simple and reliable operating principle, with minimal moving parts and robust construction ensuring long-term performance and durability. The absence of complex mechanical components such as motors, gears, or lubricants reduces maintenance requirements and enhances reliability, making pneumatic cylinders suitable for continuous-duty applications in harsh industrial environments.

- Cost-Effective Automation:

Pneumatic cylinders offer cost-effective solutions for automation tasks, providing reliable performance at a competitive price point. The widespread availability of compressed air infrastructure and pneumatic components reduces initial investment costs and operational expenses, making pneumatic systems accessible to a wide range of industries and applications. Pneumatic cylinders enable cost-effective automation in manufacturing, assembly, material handling, and other robotics applications, contributing to increased productivity and efficiency.

- Adaptability and Flexibility:

Pneumatic cylinders provide adaptability and flexibility in robotics applications, allowing robots to perform a diverse range of tasks with ease. Whether lifting, pushing, pulling, or holding objects, pneumatic cylinders offer versatile motion capabilities that can be tailored to specific task requirements. The ability to integrate pneumatic cylinders into modular and scalable automation systems enables flexibility in design and operation, accommodating changing production demands and process requirements.

Significance of Pneumatic Cylinders in Robotics:

- Versatility and Adaptability:

Pneumatic cylinders play a crucial role in enhancing the versatility and adaptability of robots, enabling them to perform a wide range of tasks in diverse environments and industries. Whether handling delicate components in electronics manufacturing or lifting heavy loads in automotive assembly, pneumatic cylinders provide the motion capabilities needed to accomplish tasks efficiently and effectively.

- Agility and Speed:

Pneumatic cylinders contribute to the agility and speed of robots, allowing them to execute rapid and precise movements with responsiveness and accuracy. The instantaneous response of compressed air enables pneumatic cylinders to achieve high acceleration and deceleration rates, making them ideal for applications requiring fast cycle times and dynamic motion control.

- Cost-Effectiveness and Affordability:

Pneumatic cylinders offer cost-effective solutions for automation tasks, providing reliable performance at a competitive price point. The simplicity of pneumatic systems, coupled with the widespread availability of compressed air infrastructure, reduces initial investment costs and operational expenses, making pneumatic cylinders accessible to a wide range of industries and applications.

- Reliability and Durability:

Pneumatic cylinders are renowned for their reliability and durability, capable of withstanding harsh operating conditions and heavy loads with minimal maintenance. The robust construction and simplicity of pneumatic cylinders ensure long-term performance and reliability, making them suitable for continuous-duty applications in industrial automation, manufacturing, and material handling.

- Innovation and Advancement:

Ongoing research and development in pneumatic cylinder technologies drive innovation and advancement in the field of robotics, unlocking new possibilities for performance, efficiency, and functionality. From advancements in materials science and manufacturing techniques to innovations in valve design and control algorithms, pneumatic cylinders continue to evolve, enabling robots to push the boundaries of speed, precision, and agility.

- Pneumatic Rotary Actuators:

Pneumatic rotary actuators enable rotational motion in pneumatic systems, offering precise control and high torque output. These actuators utilize the power of compressed air to drive rotary motion, allowing robots to perform tasks such as turning, gripping, and positioning with agility and accuracy. Pneumatic rotary actuators find applications in robotic arms, industrial manipulators, and automated machinery, where rotational motion is essential for task execution.

Pneumatic Rotary Actuators: Driving Dynamic Motion in Robotics

In the intricate landscape of robotics, where precision and versatility reign supreme, pneumatic rotary actuators stand as vital components, facilitating seamless rotational motion with remarkable efficiency and agility. Leveraging the power of compressed air, these robust devices translate pneumatic energy into rotary motion, enabling robots to perform a myriad of tasks across industries, from valve control and indexing to robotic grippers and material handling. Join us on an in-depth exploration of pneumatic rotary actuators, unraveling their types, functionalities, and pivotal role in shaping the landscape of modern robotics.

Types of Pneumatic Rotary Actuators:

Rack and Pinion Actuators:

Rack and pinion actuators are commonly used in robotics applications to convert linear motion into rotary motion. These actuators consist of a linear rack meshing with a rotary pinion gear, with compressed air applied to the rack to drive the pinion gear and produce rotational movement. Rack and pinion actuators offer simple and compact designs, making them suitable for applications such as valve control, indexing tables, and robotic arm joints.

- Vane Actuators:

Vane actuators utilize a set of vanes mounted on a rotor to convert pneumatic energy into rotary motion. As compressed air enters the actuator, it pushes against the vanes, causing the rotor to rotate and drive the output shaft. Vane actuators offer smooth and precise operation, making them suitable for applications such as robotic grippers, rotary tables, and positioning systems.

- Helical Gear Actuators:

Helical gear actuators employ helical gears to transmit rotary motion, providing smooth and quiet operation with minimal backlash. These actuators feature a helical gear meshing with a mating gear or rack, with compressed air applied to one side of the gears to drive rotation. Helical gear actuators offer high torque output and precision motion control, making them suitable for applications such as rotary indexing, robotic manipulators, and CNC machining.

- Rack and Worm Gear Actuators:

Rack and worm gear actuators combine linear rack and rotary worm gear mechanisms to produce rotary motion. These actuators feature a linear rack engaged with a rotary worm gear, with compressed air applied to the rack to drive the worm gear and rotate the output shaft. Rack and worm gear actuators offer high torque output and self-locking capabilities, making them suitable for applications such as robotic arm joints, rotary clamps, and rotary valves.

- Vortex Tube Actuators:

Vortex tube actuators utilize the principle of vortex tube technology to generate rotary motion from compressed air. These actuators feature a vortex tube that creates a swirling airflow, which is directed onto a rotor to produce rotary motion. Vortex tube actuators offer simple and compact designs, with no moving parts other than the rotor, making them suitable for applications such as rotary fans, air-driven motors, and pneumatic drills.

Functionalities of Pneumatic Rotary Actuators:

- Smooth and Precise Motion Control:

Pneumatic rotary actuators offer smooth and precise motion control, enabling robots to achieve accurate and repeatable rotational movements. By regulating the flow and pressure of compressed air, pneumatic systems can control the speed, acceleration, and deceleration of rotary actuators with precision, ensuring precise positioning and motion profiles in robotics applications.

- High Torque Output:

Pneumatic rotary actuators provide high torque output, allowing robots to exert significant rotational force for tasks such as gripping, positioning, and manipulating objects. The instantaneous response of compressed air to control signals enables pneumatic actuators to deliver rapid torque output, making them ideal for applications requiring high-speed and high-torque motion control.

- Compact and Lightweight Design:

Pneumatic rotary actuators feature compact and lightweight designs, minimizing space requirements and enabling easy integration into robotic systems. The absence of bulky motors, gearboxes, or hydraulic systems reduces overall weight and footprint, making pneumatic actuators suitable for applications where space and weight constraints are critical considerations.

- Quick and Responsive Operation:

Pneumatic rotary actuators offer quick and responsive operation, with rapid actuation times and minimal delay between input signals and motion output. The low inertia of compressed air allows pneumatic systems to achieve high acceleration and deceleration rates, enabling robots to perform rapid and agile rotational movements with precision and efficiency.

- Cost-Effective Automation:

Pneumatic rotary actuators provide cost-effective solutions for automation tasks, offering reliable performance at a competitive price point. The simplicity of pneumatic systems, coupled with the widespread availability of compressed air infrastructure, reduces initial investment costs and operational expenses, making pneumatic actuators accessible to a wide range of industries and applications.

Significance of Pneumatic Rotary Actuators in Robotics:

- Versatility and Adaptability:

Pneumatic rotary actuators play a crucial role in enhancing the versatility and adaptability of robots, enabling them to perform a wide range of rotational tasks in diverse environments and industries. Whether indexing components in manufacturing, gripping objects in material handling, or positioning tools in machining, pneumatic actuators provide the motion capabilities needed to accomplish tasks efficiently and effectively.

- Agility and Speed:

Pneumatic rotary actuators contribute to the agility and speed of robots, allowing them to execute rapid and precise rotational movements with responsiveness and accuracy. The instantaneous response of compressed air enables pneumatic actuators to achieve high acceleration and deceleration rates, making them ideal for applications requiring fast cycle times and dynamic motion control.

- Cost-Effectiveness and Affordability:

Pneumatic rotary actuators offer cost-effective solutions for automation tasks, providing reliable performance at a competitive price point. The simplicity of pneumatic systems, coupled with the widespread availability of compressed air infrastructure, reduces initial investment costs and operational expenses, making pneumatic actuators accessible to a wide range of industries and applications.

- Reliability and Durability:

Pneumatic rotary actuators are renowned for their reliability and durability, capable of withstanding harsh operating conditions and heavy loads with minimal maintenance. The robust construction and simplicity of pneumatic actuators ensure long-term performance and reliability, making them suitable for continuous-duty applications in industrial automation, manufacturing, and material handling.

- Innovation and Advancement

Ongoing research and development in pneumatic actuator technologies drive innovation and advancement in the field of robotics, unlocking new possibilities for performance, efficiency, and functionality. From advancements in materials science and manufacturing techniques to innovations in valve design and control algorithms, pneumatic actuators continue to evolve, enabling robots to push the boundaries of speed, precision, and agility.

In conclusion, pneumatic rotary actuators stand as essential components in the realm of robotics, offering dynamic rotational motion capabilities,

- Pneumatic Motors:

Pneumatic motors are specialized actuators designed to generate rotary motion directly from compressed air, offering high-speed operation and compact form factors. These motors utilize principles such as air expansion or impingement to drive rotational motion, eliminating the need for additional mechanical components such as gears or pistons. Pneumatic motors are commonly used in applications such as pneumatic drills, pneumatic wrenches, and pneumatic turbines, where lightweight, high-speed operation is essential.

- Pneumatic Muscle Actuators

Pneumatic muscle actuators, also known as pneumatic artificial muscles or pneumatic actuators, mimic the function of biological muscles by contracting and expanding in response to changes in air pressure. These actuators consist of an elastic bladder or tube surrounded by a braided sheath, with compressed air applied to inflate or deflate the bladder, causing it to contract or expand. Pneumatic muscle actuators offer lightweight, flexible, and adaptable motion capabilities, making them suitable for applications such as robotic prosthetics, exoskeletons, and soft robotics.

- Vacuum Generators

Vacuum generators are pneumatic actuators that utilize the Venturi effect to generate suction or vacuum pressure, enabling robots to grip and manipulate objects with precision and efficiency. These generators create a low-pressure environment by accelerating air through a constricted nozzle, drawing in surrounding air and creating suction. Vacuum generators are commonly used in robotic grippers, suction cups, and material handling systems, where precise object manipulation and pick-and-place operations are required.

- Pneumatic Grippers:

Pneumatic grippers facilitate the manipulation and handling of objects in robotic systems, providing a secure and versatile means of grasping and releasing items of varying shapes and sizes. These grippers employ pneumatic pressure to actuate jaws or fingers, allowing robots to grip, lift, and transport objects with precision and efficiency. Pneumatic grippers come in different designs, including parallel, angular, and three-finger configurations, each optimized for specific gripping tasks in industries such as manufacturing, logistics, and assembly.

- Pneumatic Slides:

Pneumatic slides enable linear motion in pneumatic systems, providing a smooth and reliable means of positioning and actuation. These slides utilize compressed air to drive linear motion along a guided path, allowing robots to perform tasks such as pushing, pulling, and indexing with precision and repeatability. Pneumatic slides find applications in automated assembly lines, packaging machinery, and material handling systems, where linear motion is critical for task execution and throughput optimization.

- Pneumatic Vacuum Generators:

Pneumatic vacuum generators harness the power of differential pressure to create suction force, enabling robots to grip and manipulate non-porous objects without physical contact. These generators utilize compressed air to create a vacuum within a chamber, causing atmospheric pressure to exert force on objects, securing them in place. Pneumatic vacuum generators are commonly used in pick-and-place applications, packaging systems, and robotic end-effectors, where non-contact gripping is essential for delicate or fragile objects.

Functionalities of Pneumatic Actuators:

- Speed and Agility:

Pneumatic actuators offer rapid response times and dynamic performance, enabling robots to execute tasks with agility and efficiency. Due to the compressibility of air and the absence of complex mechanical components, pneumatic actuators can achieve high speeds and accelerations, making them ideal for applications requiring rapid motion and quick cycle times. Whether performing pick-and-place operations in manufacturing or navigating obstacle-laden environments in mobile robotics, pneumatic actuators empower robots with the speed and agility needed to excel in dynamic and fast-paced environments.

- Force and Power:

Despite their lightweight and compact design, pneumatic actuators can generate significant force and power, making them suitable for a wide range of lifting, pushing, and gripping tasks. By varying the pressure and volume of compressed air, pneumatic actuators can exert force proportional to the load requirements, enabling robots to manipulate objects of varying weights and sizes with ease. From lifting heavy payloads in material handling systems to clamping workpieces in machining operations, pneumatic actuators provide the muscle needed to accomplish diverse tasks in robotics.

- Precision and Control:

Pneumatic actuators offer precise control over motion and force, allowing robots to execute tasks with accuracy and repeatability. Through the use of precision valves, regulators, and sensors, pneumatic systems can modulate air pressure, flow rates, and actuation forces with fine granularity, ensuring precise positioning and motion control. Whether maintaining tight tolerances in manufacturing processes or executing delicate maneuvers in robotic surgery, pneumatic actuators enable robots to achieve consistent and reliable performance in a wide range of applications.

- Simplicity and Reliability:

Pneumatic actuators are characterized by their simplicity and reliability, making them ideal for rugged and demanding environments. Unlike electromechanical actuators, which may be prone to mechanical wear or electrical failures, pneumatic actuators operate without the need for complex components such as motors, gears, or bearings. This simplicity reduces the risk of downtime and maintenance costs, ensuring uninterrupted operation in industrial automation, mobile robotics, and harsh operating conditions.

- Flexibility and Adaptability:

Pneumatic actuators offer inherent flexibility and adaptability, allowing robots to perform a wide range of tasks and maneuvers with minimal adjustments or reconfiguration. By modulating air pressure, flow rates, and actuation parameters, pneumatic systems can adapt their behavior to changing task requirements or environmental conditions, enabling robots to respond dynamically to unforeseen obstacles, variations in load, or changes in terrain. This flexibility is particularly valuable in applications such as assembly automation, where robots must accommodate diverse product configurations and production schedules while maintaining optimal performance.

Significance of Pneumatic Actuators in Robotics:

- Efficiency and Energy Optimization:

Pneumatic actuators are known for their efficiency and energy optimization, leveraging the compressibility of air to achieve high power output with minimal energy consumption. By utilizing energy-efficient components such as pneumatic valves, regulators, and actuators, pneumatic systems can maximize energy transfer and minimize losses, ensuring optimal performance and sustainability in robotic operations. This energy efficiency is essential for reducing operational costs and environmental impact, particularly in applications such as manufacturing, where energy consumption is a significant factor in production efficiency.

- Safety and Compliance:

Pneumatic actuators prioritize safety and compliance in robotic operations, incorporating safety features such as pressure relief valves, flow restrictors, and emergency stop systems to prevent accidents and ensure operator safety. By implementing fail-safe mechanisms and interlocks, pneumatic systems can mitigate the risk of overloading, leakage, or sudden actuator failure, enhancing the safety and reliability of robotic operations in industrial, medical, and hazardous environments. This focus on safety and compliance is critical for regulatory compliance and risk management in robotics, ensuring the protection of human operators and assets.

- Cost-Effectiveness and Scalability:

Pneumatic actuators offer cost-effective solutions for robotic automation, providing high performance and reliability at a competitive price point. Compared to electromechanical actuators or hydraulic systems, pneumatic actuators require less complex infrastructure, maintenance, and operational costs, making them an attractive option for small to medium-sized enterprises (SMEs) and emerging industries. Additionally, pneumatic systems are scalable and modular, allowing for easy integration and expansion as robotic applications evolve and grow in complexity. This cost-effectiveness and scalability enable pneumatic actuators to play