Introduction:

In the dynamic landscape of modern commerce, efficiency is key. The intricate dance of global supply chains demands precision, speed, and adaptability. Enter logistics robots, the mechanical marvels reshaping the way goods are moved, sorted, and delivered. From bustling warehouses to sprawling distribution centers, these autonomous machines are revolutionizing the logistics industry, offering unprecedented levels of efficiency, accuracy, and scalability.

The Evolution of Logistics Robots:

The journey of logistics robots traces back to the early experiments in automation. Initially, robots were deployed for simple tasks such as palletizing and stacking. However, advancements in artificial intelligence, sensor technology, and robotics have propelled these machines beyond their rudimentary beginnings. Today’s logistics robots are sophisticated systems capable of navigating complex environments, interacting with humans, and making real-time decisions.

The Evolution of Logistics Robots: Transforming Supply Chains Through Automation

Introduction:

In the intricate web of modern commerce, the efficient movement of goods is paramount. Over the years, the logistics industry has witnessed a remarkable evolution driven by technological advancements. At the forefront of this transformation are logistics robots, whose journey from rudimentary machines to sophisticated automated systems has revolutionized the way goods are handled, sorted, and delivered. This exploration delves into the rich history and evolution of logistics robots, tracing their trajectory from humble beginnings to indispensable components of contemporary supply chains.

Origins of Logistics Automation:

The roots of logistics automation can be traced back to the mid-20th century when industries began experimenting with mechanized solutions to streamline their operations. Early iterations of logistics robots were rudimentary and primarily focused on repetitive tasks such as palletizing and stacking. These machines, though primitive by today’s standards, laid the groundwork for the future development of more sophisticated robotic systems.

Advancements in Robotics Technology:

The evolution of logistics robots gained momentum with advancements in robotics technology. The integration of sensors, actuators, and artificial intelligence (AI) algorithms enabled robots to perceive and interact with their environments more effectively. Mobile robots, such as Automated Guided Vehicles (AGVs), emerged as a viable solution for material handling tasks within warehouses and distribution centers. These early robots were programmed to follow predetermined paths, marking a significant leap forward in automation capabilities.

The Rise of Autonomous Systems:

The dawn of the 21st century witnessed a paradigm shift in logistics robotics with the advent of autonomous systems. These robots, equipped with advanced sensors and AI algorithms, possess the ability to navigate dynamic environments, make real-time decisions, and adapt to changing conditions autonomously. Collaborative robots, or cobots, entered the scene, working alongside human workers to perform tasks requiring dexterity and flexibility. The integration of robotics and AI paved the way for a new era of efficiency and productivity in the logistics industry.

Applications Across the Supply Chain:

Logistics robots have found applications across various stages of the supply chain, from manufacturing facilities to distribution centers and beyond. In warehouses, robots handle tasks such as picking, packing, and sorting with unparalleled speed and accuracy, reducing cycle times and labor costs. Autonomous drones take to the skies, offering rapid and flexible delivery solutions for last-mile logistics. At ports and terminals, automated cranes and vehicles streamline the movement of containers, optimizing throughput and reducing congestion. The versatility of logistics robots makes them indispensable assets in the modern supply chain ecosystem.

Challenges and Opportunities:

Despite their transformative potential, logistics robots face several challenges that must be addressed to realize their full benefits. Integration into existing infrastructure requires significant investments in both technology and personnel training. Concerns about job displacement and workforce reskilling necessitate careful planning and collaboration between stakeholders. Moreover, issues related to safety, reliability, and cybersecurity pose ongoing challenges for robotics deployment. However, these challenges also present opportunities for innovation and collaboration, as industry stakeholders work together to overcome obstacles and unlock the full potential of logistics robots.

Future Trends and Outlook:

Looking ahead, the future of logistics robots appears promising, with continued advancements in technology driving innovation and adoption. Machine learning algorithms will enable robots to learn and adapt to their environments more effectively, enhancing their capabilities and performance. The proliferation of cloud computing and connectivity will facilitate the integration of robotics systems into broader digital ecosystems, enabling seamless communication and coordination across supply chain networks. As robotics technology continues to evolve, logistics robots will play an increasingly central role in shaping the future of commerce, driving efficiency, sustainability, and competitiveness.

Conclusion:

The evolution of logistics robots represents a transformative journey that has reshaped the way goods are moved, sorted, and delivered. From their humble origins to their current state of sophistication, logistics robots have revolutionized the logistics industry, offering unprecedented levels of efficiency, accuracy, and scalability. As technology continues to advance, logistics robots will continue to evolve, driving innovation and reshaping the future of supply chain management. With careful planning, investment, and collaboration, logistics robots will unlock new opportunities for businesses to thrive in an increasingly complex and dynamic global marketplace.

Types of Logistics Robots:

Logistics robots come in various shapes and sizes, each tailored to specific tasks within the supply chain ecosystem. Automated Guided Vehicles (AGVs) roam the floors of warehouses, transporting goods from one location to another with precision and efficiency. Collaborative robots, or cobots, work alongside human workers, assisting with tasks like picking, packing, and sorting. Autonomous drones take to the skies, offering swift and flexible delivery solutions for last-mile logistics. Each type of robot brings unique capabilities to the table, contributing to a seamless and integrated supply chain network.

Exploring the Diverse Landscape: Types of Logistics Robotics in Supply Chain Management

Introduction:

In the ever-evolving landscape of supply chain management, the integration of robotics has emerged as a pivotal driver of efficiency, accuracy, and scalability. From warehouses to distribution centers, logistics robots have become indispensable assets, revolutionizing the way goods are handled, sorted, and delivered. This exploration delves into the diverse array of logistics robotics, highlighting their unique capabilities and applications across the supply chain ecosystem.

Automated Guided Vehicles (AGVs):

Automated Guided Vehicles (AGVs) represent one of the foundational pillars of logistics robotics. These autonomous mobile robots navigate predefined paths within warehouses and distribution centers, transporting goods between various locations with precision and efficiency. AGVs come in various forms, including forklifts, pallet trucks, and tuggers, each tailored to specific material handling tasks. Equipped with sensors and navigation systems, AGVs can safely maneuver through dynamic environments, optimizing throughput and minimizing operational costs.

Autonomous Mobile Robots (AMRs):

Autonomous Mobile Robots (AMRs) represent the next evolution in logistics robotics, offering greater flexibility and adaptability compared to traditional AGVs. Unlike AGVs, which rely on predefined paths, AMRs leverage onboard sensors and AI algorithms to navigate autonomously in dynamic environments. These versatile robots can perform a wide range of tasks, including picking, packing, and sorting, making them ideal for agile and rapidly changing warehouse operations. With their ability to learn and adapt to new environments, AMRs offer unparalleled levels of efficiency and scalability in supply chain management.

Collaborative Robots (Cobots):

Collaborative Robots, or Cobots, bridge the gap between humans and machines, offering a symbiotic approach to logistics operations. Unlike traditional industrial robots, which operate within fenced-off areas, cobots are designed to work alongside human workers in shared workspaces. Cobots excel in tasks that require dexterity, precision, and human oversight, such as order picking, kitting, and assembly. With built-in safety features and intuitive interfaces, cobots enhance productivity while ensuring a safe and collaborative work environment for human workers.

Autonomous Drones:

Autonomous drones have emerged as disruptive technology in last-mile logistics, offering swift and flexible delivery solutions for urban and remote areas. These unmanned aerial vehicles (UAVs) can navigate congested airspace and deliver packages to customers’ doorsteps with unprecedented speed and efficiency. Equipped with advanced sensors and GPS navigation systems, autonomous drones can overcome geographical barriers and deliver goods to remote or hard-to-reach locations. While regulatory challenges and airspace management remain significant hurdles, the potential of autonomous drones to revolutionize last-mile delivery is undeniable.

Robotic Arms and Manipulators:

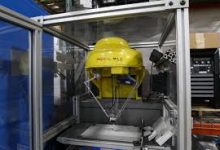

Robotic arms and manipulators play a critical role in logistics operations, performing tasks that require precision and dexterity, such as palletizing, depalletizing, and bin picking. These articulated robotic arms are equipped with grippers, suction cups, and other end-of-arm tooling (EOAT) to handle a wide range of objects and materials. With advances in AI and computer vision, robotic arms can identify and manipulate objects with human-like dexterity, enabling efficient and cost-effective automation of manual tasks in warehouses and distribution centers.

Automated Sorting Systems:

Automated sorting systems utilize a combination of conveyor belts, sensors, and robotics to streamline the sorting process in distribution centers and fulfillment centers. These systems can handle large volumes of packages and parcels, sorting them based on predefined criteria such as destination, size, or weight. Robotic arms and actuators play a crucial role in diverting packages to the appropriate chute or conveyor belt, ensuring accurate and efficient sorting operations. Automated sorting systems are essential for optimizing throughput and minimizing bottlenecks in high-volume distribution facilities.

Conclusion:

The diverse landscape of logistics robotics offers a plethora of solutions to address the complex challenges of modern supply chain management. From Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) to Collaborative Robots (Cobots) and Autonomous Drones, each type of logistics robot brings unique capabilities and applications to the table. By leveraging these technologies, businesses can optimize their operations, enhance productivity, and deliver superior customer experiences in an increasingly competitive marketplace. As technology continues to advance, the role of logistics robotics will only continue to grow, driving innovation and reshaping the future of supply chain management.

Benefits of Logistics Robots:

The adoption of logistics robots offers a plethora of benefits to businesses operating in today’s fast-paced environment. Improved efficiency is perhaps the most obvious advantage, as robots can work around the clock without fatigue or error. Enhanced accuracy minimizes costly mistakes and reduces the risk of inventory discrepancies. Moreover, robots can handle repetitive or hazardous tasks, freeing up human workers to focus on more strategic activities. Ultimately, the integration of logistics robots results in faster fulfillment, lower costs, and increased customer satisfaction.

Unlocking Efficiency and Innovation: Exploring the Benefits of Logistics Robots in Supply Chain Management

Introduction:

In the fast-paced world of supply chain management, the integration of robotics has emerged as a transformative force, revolutionizing the way goods are handled, sorted, and delivered. Logistics robots, equipped with advanced sensors, AI algorithms, and autonomous capabilities, offer a wide array of benefits to businesses seeking to optimize their operations and stay ahead of the competition. This exploration delves into the myriad advantages of logistics robots, from enhanced efficiency and accuracy to improved safety and scalability.

Improved Efficiency:

At the heart of logistics robotics lies the promise of improved efficiency. By automating repetitive and labor-intensive tasks, robots can operate around the clock without fatigue or error, optimizing throughput and minimizing cycle times. Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) excel in material handling tasks, streamlining the movement of goods within warehouses and distribution centers. With their ability to navigate autonomously and adapt to changing conditions, logistics robots ensure smooth and uninterrupted operations, driving efficiency gains throughout the supply chain.

Enhanced Accuracy:

Logistics robots are renowned for their precision and accuracy, minimizing errors and reducing the risk of inventory discrepancies. Automated picking and sorting systems leverage advanced sensors and computer vision technology to identify and handle items with unparalleled speed and accuracy. Collaborative Robots (Cobots) work alongside human workers, providing assistance and oversight in tasks that require dexterity and attention to detail. By eliminating manual handling errors and reducing product damage, logistics robots ensure the integrity and reliability of the supply chain, enhancing customer satisfaction and loyalty.

Cost Reduction:

The adoption of logistics robots offers significant cost savings for businesses across the supply chain. By automating repetitive tasks and reducing reliance on manual labor, robots help minimize labor costs and optimize resource allocation. Moreover, the improved efficiency and accuracy provided by logistics robots result in lower operational expenses, reduced inventory carrying costs, and decreased order fulfillment times. With a lower cost per unit processed, businesses can achieve higher profitability and remain competitive in today’s dynamic marketplace.

Increased Flexibility and Scalability:

Logistics robots offer unparalleled levels of flexibility and scalability, allowing businesses to adapt quickly to changing demand patterns and market conditions. Unlike traditional manual labor, robots can be easily reprogrammed and redeployed to perform different tasks or accommodate fluctuations in workload. Autonomous Mobile Robots (AMRs) can navigate dynamic environments and adjust their routes in real-time, ensuring efficient utilization of space and resources. With the ability to scale operations up or down as needed, logistics robots provide businesses with the agility and responsiveness required to thrive in a rapidly changing business environment.

Improved Safety:

Safety is a top priority in any logistics operation, and logistics robots play a crucial role in enhancing workplace safety and reducing the risk of accidents and injuries. By automating hazardous tasks and reducing the need for human intervention in dangerous environments, robots help create safer working conditions for employees. Collaborative Robots (Cobots) are specifically designed to work alongside human workers, employing advanced safety features such as sensors and collision avoidance systems to prevent accidents and ensure safe interaction. With robots handling high-risk tasks, employees can focus on more value-added activities, leading to a safer and more productive work environment.

Innovation and Competitive Advantage:

The adoption of logistics robots fosters innovation and drives competitive advantage for businesses seeking to differentiate themselves in the market. By leveraging cutting-edge technology and automation solutions, companies can optimize their operations, reduce time-to-market, and deliver superior customer experiences. Logistics robots enable businesses to explore new business models, such as on-demand delivery and personalized services, that were previously unattainable with traditional manual labor. By embracing robotics technology, businesses can position themselves as industry leaders and pioneers in supply chain innovation.

Conclusion:

The benefits of logistics robots are manifold, spanning efficiency, accuracy, cost reduction, flexibility, safety, and innovation. By leveraging robotics technology, businesses can optimize their operations, enhance productivity, and gain a competitive edge in today’s dynamic marketplace. As technology continues to advance and robotics solutions become more accessible, the role of logistics robots will only continue to grow, driving innovation and reshaping the future of supply chain management.

Challenges and Considerations:

Despite their transformative potential, logistics robots are not without challenges. Integration into existing infrastructure can be complex and costly, requiring careful planning and investment. Concerns surrounding job displacement and workforce reskilling also loom large, prompting discussions about the future of human labor in an increasingly automated world. Additionally, issues related to safety, reliability, and cybersecurity must be addressed to ensure the seamless operation of robotics systems. Overcoming these challenges will be crucial in harnessing the full potential of logistics robots while mitigating associated risks.

Navigating the Terrain: Addressing the Challenges and Considerations of Implementing Logistics Robots

Introduction:

While the integration of robotics in supply chain management holds tremendous promise for efficiency and innovation, it also presents a myriad of challenges and considerations that businesses must navigate. From technological complexities to workforce implications, regulatory hurdles, and ethical concerns, the adoption of logistics robots requires careful planning, investment, and collaboration. This exploration delves into the multifaceted challenges and considerations of implementing logistics robots, offering insights into how businesses can overcome obstacles and maximize the benefits of automation.

Technological Complexity:

One of the primary challenges of implementing logistics robots lies in the technological complexity inherent in robotics systems. From hardware components to software algorithms and integration with existing infrastructure, deploying and managing logistics robots requires specialized expertise and resources. Businesses must invest in robust training programs and technical support to ensure the successful implementation and maintenance of robotics solutions. Moreover, as robotics technology continues to advance, businesses must stay abreast of the latest developments and trends to remain competitive in the rapidly evolving landscape.

Integration into Existing Infrastructure:

Integrating logistics robots into existing infrastructure poses significant logistical and operational challenges for businesses. Warehouses and distribution centers are often complex environments with diverse layouts, workflows, and systems. Retrofitting these facilities to accommodate robotics systems requires careful planning and coordination to minimize disruption to ongoing operations. Businesses must assess their current infrastructure and workflows to identify areas where robotics automation can provide the most significant benefits and develop a roadmap for phased implementation.

Workforce Implications:

The adoption of logistics robots inevitably raises concerns about the impact on the workforce. While robots can automate repetitive and labor-intensive tasks, they also have the potential to displace human workers, leading to job loss and economic disruption. Businesses must proactively address these workforce implications by investing in workforce reskilling and upskilling programs to equip employees with the skills needed to thrive in an increasingly automated environment. Moreover, businesses can leverage robotics technology to augment human capabilities, creating new roles and opportunities for employees to contribute value in areas such as robotics maintenance, programming, and supervision.

Regulatory and Compliance Considerations:

Logistics robots operate within a complex regulatory landscape governed by safety standards, labor laws, and industry regulations. Businesses must ensure that their robotics systems comply with applicable regulations and standards to mitigate the risk of fines, penalties, or legal liabilities. Moreover, as robotics technology continues to advance, policymakers and regulators may introduce new regulations to address emerging concerns such as data privacy, cybersecurity, and ethical considerations. Businesses must stay informed about regulatory developments and engage with policymakers to shape regulatory frameworks that support innovation while ensuring safety, fairness, and accountability.

Ethical and Societal Implications:

The adoption of logistics robots raises ethical and societal implications that businesses must carefully consider. Concerns about job displacement, income inequality, and the widening digital divide require thoughtful reflection and proactive measures to address. Moreover, as robots become increasingly autonomous and capable of making decisions independently, questions about accountability, transparency, and bias in algorithmic decision-making emerge. Businesses must prioritize ethical considerations in the design, deployment, and use of robotics systems, ensuring that they align with broader societal values and contribute to positive social outcomes.

Maintenance and Reliability:

Ensuring the ongoing maintenance and reliability of logistics robots is essential to their long-term success. Like any mechanical system, robots require regular maintenance, repairs, and upgrades to ensure optimal performance and uptime. Businesses must establish robust maintenance procedures and schedules to identify and address issues proactively. Moreover, businesses must have contingency plans in place to mitigate the impact of unexpected downtime or system failures on operations. Investing in redundancy, backup systems, and disaster recovery measures can help minimize disruptions and ensure continuity of operations in the event of technical failures or emergencies.

Conclusion:

The challenges and considerations of implementing logistics robots are complex and multifaceted, requiring careful planning, investment, and collaboration across various stakeholders. By addressing technological complexities, integrating robots into existing infrastructure, addressing workforce implications, navigating regulatory and compliance considerations, considering ethical and societal implications, and ensuring maintenance and reliability, businesses can overcome obstacles and maximize the benefits of automation. With strategic foresight and proactive measures, businesses can harness the transformative power of logistics robots to drive efficiency, innovation, and competitiveness in supply chain management.

Future Outlook:

Looking ahead, the future of logistics robots appears bright and promising. As technology continues to advance, robots will become even more intelligent, agile, and adaptable. Machine learning algorithms will enable robots to optimize their operations autonomously, learning from past experiences and adjusting to changing conditions in real-time. Collaboration between humans and robots will deepen, ushering in an era of augmented intelligence where humans and machines work together synergistically. Ultimately, logistics robots will play a central role in shaping the future of supply chain management, driving innovation, efficiency, and sustainability.

Conclusion:

In the ever-evolving world of logistics, robots are not just tools; they are catalysts for transformation. By harnessing the power of automation, businesses can unlock new levels of efficiency, agility, and competitiveness. However, the journey towards fully automated supply chains is not without its challenges. It requires careful planning, investment, and collaboration across various stakeholders. Yet, the rewards are substantial, with the potential to revolutionize the way goods are produced, distributed, and consumed. As logistics robots continue to evolve and mature, one thing is certain: they will remain at the forefront of innovation, shaping the future of commerce for years to come.