Functionality Of Industrial Robotics

Introduction:

Industrial robotics stands as the cornerstone of modern manufacturing, driving efficiency, precision, and innovation across various industries. These versatile machines are designed to automate repetitive tasks, handle complex processes, and operate in diverse environments, revolutionizing production processes and enhancing competitiveness. This comprehensive exploration delves into the functionality of industrial robotics, unraveling their capabilities, applications, and transformative impact on manufacturing operations.

-

Automating Repetitive Tasks:

One of the primary functions of industrial robotics is to automate repetitive tasks that are labor-intensive, monotonous, and prone to human error. Robots excel in tasks such as material handling, assembly, and packaging, where precision, consistency, and repeatability are essential for maintaining quality and efficiency. By automating these tasks, industrial robots enable manufacturers to streamline production processes, reduce cycle times, and optimize resource utilization, ultimately leading to cost savings and improved productivity.

Unleashing Efficiency: The Role of Robotics in Automating Repetitive Tasks

-

Introduction:

In the realm of manufacturing and beyond, the automation of repetitive tasks stands as a cornerstone of efficiency and productivity. Industrial robotics have emerged as indispensable tools for automating mundane, labor-intensive tasks, enabling manufacturers to streamline production processes, enhance quality, and reduce costs. This comprehensive exploration delves into the intricacies of automating repetitive tasks with robotics, unraveling their capabilities, applications, and transformative impact on manufacturing operations.

-

The Need for Automation:

Repetitive tasks, characterized by their repetitive nature, require consistent and precise execution to maintain quality and efficiency. However, relying solely on human labor for these tasks can lead to challenges such as fatigue, inconsistency, and inefficiency. Automating repetitive tasks with robotics addresses these challenges by leveraging the speed, accuracy, and reliability of machines, allowing manufacturers to achieve higher levels of productivity and quality while reducing reliance on manual labor.

-

Streamlining Production Processes:

Industrial robots excel in automating a wide range of repetitive tasks, including material handling, assembly, packaging, and inspection. These robots are equipped with advanced sensors, actuators, and control systems that enable precise and repeatable motion, ensuring consistent performance even in complex manufacturing environments. By automating these tasks, manufacturers can streamline production processes, reduce cycle times, and optimize resource utilization, ultimately improving overall efficiency and competitiveness.

-

Enhancing Quality and Consistency:

One of the key benefits of automating repetitive tasks with robotics is the ability to enhance quality and consistency. Unlike human operators, robots do not experience fatigue or distractions, allowing them to perform tasks with unparalleled precision and repeatability. This results in products of consistent quality, free from errors or defects caused by human variability. Moreover, robots equipped with advanced sensors and vision systems can perform real-time quality inspection and feedback, ensuring compliance with stringent standards and specifications.

-

Improving Workforce Efficiency:

By automating repetitive tasks, robotics technology frees up human workers to focus on more value-added activities that require creativity, problem-solving, and decision-making skills. Rather than performing monotonous and physically demanding tasks, human operators can oversee and supervise automated processes, troubleshoot issues, and optimize production workflows. This not only improves workforce efficiency but also enhances job satisfaction and engagement, leading to a more motivated and productive workforce.

-

Reducing Costs and Increasing ROI:

While the initial investment in robotics technology may be substantial, the long-term benefits of automating repetitive tasks far outweigh the costs. Industrial robots offer a high return on investment (ROI) by reducing labor costs, minimizing scrap and rework, and increasing throughput and yield. Additionally, robots enable manufacturers to operate more efficiently, reducing overhead costs associated with manual labor, such as training, supervision, and employee turnover. Moreover, robotics technology continues to evolve, driving down costs and increasing accessibility, making automation an attractive option for businesses of all sizes.

-

Applications Across Industries:

The applications of robotics in automating repetitive tasks span across various industries, including automotive, electronics, consumer goods, and pharmaceuticals. In automotive manufacturing, robots perform tasks such as welding, painting, and assembly of vehicle components with precision and speed. In electronics manufacturing, robots handle tasks such as pick-and-place assembly, soldering, and testing of electronic components. In consumer goods manufacturing, robots are employed for tasks such as packaging, labeling, and palletizing. Moreover, robots find applications in pharmaceutical manufacturing for tasks such as dispensing, filling, and packaging of pharmaceutical products.

-

Conclusion:

In conclusion, automating repetitive tasks with robotics technology represents a paradigm shift in manufacturing, enabling manufacturers to achieve higher levels of efficiency, productivity, and quality. By leveraging the speed, accuracy, and reliability of robots, manufacturers can streamline production processes, enhance workforce efficiency, and reduce costs. Embracing automation not only drives operational excellence but also fosters innovation and competitiveness in the dynamic landscape of modern manufacturing. As robotics technology continues to evolve, the possibilities for automating repetitive tasks are limitless, unlocking new opportunities for efficiency and productivity across industries.

-

Handling Complex Processes:

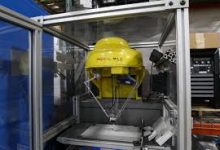

Industrial robots are capable of handling complex processes that require precision, dexterity, and adaptability beyond human capabilities. In industries such as automotive manufacturing, robots perform tasks such as welding, painting, and machining with unparalleled accuracy and efficiency. Advanced robotic systems equipped with multi-axis manipulators, sensors, and vision systems can perform intricate operations such as part inspection, surface finishing, and quality control, ensuring compliance with stringent standards and specifications. Moreover, robots are increasingly employed in industries such as electronics and aerospace for tasks such as soldering, micro-assembly, and composites manufacturing, where precision and reliability are paramount.

Mastering Complexity: Robotics’ Role in Handling Complex Processes

-

Introduction:

In the modern era of manufacturing, the ability to handle complex processes efficiently and effectively is paramount for staying competitive. Industrial robotics have emerged as indispensable tools for mastering complexity, enabling manufacturers to tackle intricate tasks with precision, speed, and reliability. This comprehensive exploration delves into the intricacies of robotics’ role in handling complex processes, unraveling its capabilities, applications, and transformative impact on manufacturing operations.

-

Understanding Complexity in Manufacturing:

Complex processes in manufacturing encompass a wide range of tasks that require precision, dexterity, and adaptability beyond human capabilities. These processes may involve intricate assembly operations, precision machining, delicate handling of materials, or compliance with stringent quality standards and specifications. Handling complexity in manufacturing requires advanced technologies and methodologies that can address the intricacies of the task at hand while ensuring efficiency, reliability, and quality.

-

Precision Machining and Assembly:

One of the key areas where robotics excel in handling complex processes is precision machining and assembly. Industrial robots equipped with multi-axis manipulators, high-speed spindles, and advanced tooling can perform intricate machining operations with unparalleled accuracy and repeatability. These robots excel in tasks such as milling, drilling, grinding, and finishing of components with tight tolerances and complex geometries. Moreover, robots are employed in precision assembly operations, where they manipulate small parts and delicate components with precision and dexterity, ensuring proper fit and alignment.

-

Quality Control and Inspection:

Quality control and inspection are critical aspects of handling complex processes in manufacturing, ensuring that products meet stringent standards and specifications. Robotics technology plays a crucial role in automating inspection tasks, enabling real-time monitoring and analysis of product quality and integrity. Robots equipped with sensors, vision systems, and measurement tools can perform non-destructive testing (NDT), dimensional inspection, and surface analysis with high accuracy and reliability. Automated inspection systems enhance process efficiency, reduce the risk of defects, and ensure compliance with regulatory requirements.

-

Material Handling and Logistics:

Material handling and logistics represent another area where robotics technology is instrumental in handling complex processes. Industrial robots equipped with advanced grippers, conveyors, and palletizers can handle a wide range of materials, including raw materials, work-in-progress, and finished products, with speed and precision. These robots excel in tasks such as sorting, picking, packing, and palletizing, optimizing material flow and logistics operations. Automated material handling systems enable manufacturers to achieve efficient, just-in-time production processes, reducing lead times and inventory costs.

-

Adapting to Dynamic Environments:

Handling complex processes in manufacturing often requires the ability to adapt to dynamic and unpredictable environments. Industrial robots equipped with advanced sensors, actuators, and control systems can adapt to changes in the production environment and adjust their behavior accordingly. These robots can perform tasks such as path planning, obstacle avoidance, and trajectory optimization in real-time, ensuring safe and efficient operation in dynamic environments. Moreover, collaborative robots, or cobots, are designed to work alongside human operators, providing additional flexibility and adaptability in shared workspaces.

-

Applications Across Industries:

The applications of robotics in handling complex processes span across various industries, including automotive, aerospace, electronics, and pharmaceuticals. In automotive manufacturing, robots are used for tasks such as precision machining, welding, and assembly of vehicle components. In aerospace manufacturing, robots handle tasks such as composites layup, drilling, and riveting of aircraft structures. In electronics manufacturing, robots perform tasks such as soldering, pick-and-place assembly, and testing of electronic components. Moreover, robots find applications in pharmaceutical manufacturing for tasks such as dispensing, filling, and packaging of pharmaceutical products.

Conclusion:

In conclusion, robotics technology plays a pivotal role in handling complex processes in manufacturing, enabling manufacturers to achieve higher levels of efficiency, precision, and quality. By leveraging advanced sensors, actuators, and control systems, robots can tackle intricate tasks with speed, accuracy, and reliability, driving innovation and competitiveness in the dynamic landscape of modern manufacturing. Embracing robotics technology empowers manufacturers to master complexity, adapt to changing market demands, and thrive in the digital age of manufacturing. As robotics technology continues to evolve, the possibilities for handling complex processes are limitless, unlocking new opportunities for efficiency, productivity, and innovation across industries.

Enhancing Flexibility and Adaptability:

One of the key advantages of industrial robotics is their flexibility and adaptability to changing production requirements and market demands. Unlike traditional manufacturing systems that are rigid and inflexible, robots can be reprogrammed and reconfigured to perform different tasks and adapt to varying production volumes and product specifications. This versatility enables manufacturers to achieve agile and responsive production processes, reducing time-to-market and facilitating product customization. Moreover, collaborative robots, or cobots, are designed to work alongside human operators, providing additional flexibility and versatility in shared workspaces.

Unleashing Agility: Robotics’ Role in Enhancing Flexibility and Adaptability in Manufacturing

Introduction:

In today’s rapidly changing business landscape, flexibility and adaptability have become critical attributes for success in manufacturing. Industrial robotics have emerged as key enablers of agility, empowering manufacturers to respond quickly to market demands, customize products, and optimize production processes. This comprehensive exploration delves into the intricacies of robotics’ role in enhancing flexibility and adaptability, unraveling its capabilities, applications, and transformative impact on manufacturing operations.

Understanding Flexibility and Adaptability:

Flexibility and adaptability in manufacturing refer to the ability to quickly adjust production processes, resources, and workflows in response to changing market conditions, customer requirements, and operational challenges. Flexible manufacturing systems (FMS) are characterized by their ability to produce a wide range of products with minimal setup time and reconfiguration. Adaptability, on the other hand, entails the ability to respond proactively to unforeseen events, disruptions, and opportunities, while maintaining efficiency and quality.

Reconfigurable Production Systems:

Industrial robots play a crucial role in enabling reconfigurable production systems, where production equipment and resources can be quickly reconfigured and repurposed to accommodate changes in product design, volume, or demand. Robots equipped with modular end-effectors, interchangeable tooling, and flexible workstations can adapt to different tasks and product variants with minimal downtime. Reconfigurable robotic cells enable manufacturers to achieve rapid changeovers, reduce setup times, and increase overall production flexibility.

Agile Manufacturing Processes:

Agile manufacturing processes leverage robotics technology to enable dynamic and responsive production workflows that can adapt to changing requirements and market demands. Industrial robots equipped with advanced sensors, actuators, and control systems can perform tasks such as path planning, obstacle avoidance, and collaborative operation in real-time, enabling seamless integration of human and machine resources. Moreover, collaborative robots, or cobots, are designed to work alongside human operators, providing additional flexibility and versatility in shared workspaces.

Just-in-Time Production:

Just-in-time (JIT) production is a manufacturing strategy that aims to minimize inventory levels and production lead times by synchronizing production with demand. Industrial robots play a crucial role in JIT production systems by enabling efficient and flexible material handling, assembly, and logistics operations. Robots equipped with advanced vision systems and adaptive control algorithms can optimize material flow, schedule production orders, and adapt to changes in demand in real-time, ensuring that production remains aligned with customer requirements.

Customization and Personalization:

In today’s consumer-driven market, customization and personalization have become key drivers of competitiveness and customer satisfaction. Industrial robots enable manufacturers to offer customized products and personalized experiences by automating tasks such as assembly, packaging, and labeling with high precision and flexibility. Robots equipped with vision systems and machine learning algorithms can adapt to variations in product design, size, and configuration, enabling mass customization and batch-of-one production.

Applications Across Industries:

The applications of robotics in enhancing flexibility and adaptability span across various industries, including automotive, electronics, consumer goods, and pharmaceuticals. In automotive manufacturing, robots are used for tasks such as flexible assembly, painting, and material handling, enabling agile production of diverse vehicle models and configurations. In electronics manufacturing, robots handle tasks such as pick-and-place assembly, soldering, and testing of electronic components, accommodating rapid changes in product designs and specifications. Moreover, robots find applications in consumer goods manufacturing for tasks such as packaging, labeling, and palletizing, facilitating customization and personalization of products.

Conclusion:

In conclusion, robotics technology plays a pivotal role in enhancing flexibility and adaptability in manufacturing, enabling manufacturers to achieve higher levels of agility, responsiveness, and competitiveness. By leveraging robotics technology, manufacturers can create reconfigurable production systems, agile manufacturing processes, and just-in-time production workflows that can adapt to changing market conditions and customer requirements. Embracing robotics technology empowers manufacturers to unleash agility, drive innovation, and thrive in the dynamic landscape of modern manufacturing. As robotics technology continues to evolve, the possibilities for enhancing flexibility and adaptability are limitless, unlocking new opportunities for efficiency, productivity, and customization across industries.

Improving Workplace Safety:

Industrial robots play a crucial role in improving workplace safety by automating hazardous tasks and reducing the risk of accidents and injuries associated with manual labor. By handling tasks such as heavy lifting, repetitive motion, and exposure to hazardous materials, robots minimize the physical strain on human workers and create safer working environments. Moreover, collaborative robots are equipped with advanced safety features such as force limiting, speed monitoring, and collision detection, ensuring safe operation in proximity to human operators. These safety features enable robots to work alongside humans in shared workspaces without the need for physical barriers or safety cages, further enhancing workplace safety and ergonomics.

Ensuring Safety: Robotics’ Role in Improving Workplace Safety

Introduction:

Workplace safety stands as a fundamental priority for businesses across all industries. In manufacturing environments, where workers interact with heavy machinery, hazardous materials, and complex processes, ensuring safety is paramount. Industrial robotics have emerged as invaluable assets in enhancing workplace safety, minimizing accidents, and creating safer working environments. This comprehensive exploration delves into the intricacies of robotics’ role in improving workplace safety, unraveling its capabilities, applications, and transformative impact on manufacturing operations.

Understanding Workplace Safety:

Workplace safety encompasses a wide range of practices and measures aimed at protecting the health, well-being, and physical integrity of workers in the workplace. In manufacturing environments, safety hazards such as moving machinery, sharp objects, heavy loads, and chemical exposures pose significant risks to workers’ safety and health. Employers are responsible for implementing safety protocols, providing training, and adopting technologies that mitigate risks and prevent accidents.

Robotic Automation of Hazardous Tasks:

One of the primary ways in which robotics improve workplace safety is by automating hazardous tasks that pose risks to human workers. Industrial robots excel in tasks such as material handling, welding, painting, and machine tending, which involve exposure to heavy loads, high temperatures, toxic fumes, and repetitive motion. By automating these tasks, robots minimize the risk of accidents, injuries, and occupational illnesses, protecting human workers from potential harm.

Collaborative Robotics:

Collaborative robots, or cobots, are specifically designed to work alongside human operators in shared workspaces, enabling safe and efficient collaboration. Unlike traditional industrial robots that operate behind safety cages, cobots are equipped with advanced safety features such as force limiting, speed monitoring, and collision detection, ensuring safe operation in proximity to humans. Cobots are employed in tasks such as assembly, inspection, and material handling, where close interaction with human workers is required.

Ergonomic Support and Assistance:

Industrial robots provide ergonomic support and assistance to human workers by handling heavy loads, repetitive tasks, and physically demanding operations. By offloading these tasks to robots, human workers experience reduced physical strain, fatigue, and risk of musculoskeletal injuries such as strains and sprains. Moreover, collaborative robots are designed to adapt to human ergonomics and work alongside human operators in a way that minimizes stress and discomfort, enhancing overall workplace ergonomics.

Hazardous Environment Operations:

Industrial robots are deployed in hazardous environments such as chemical plants, nuclear facilities, and offshore oil rigs, where human workers may be exposed to risks such as toxic chemicals, radiation, and extreme temperatures. Robots equipped with specialized sensors, actuators, and protective enclosures can operate safely in these environments, performing tasks such as inspection, maintenance, and decontamination without exposing human workers to harm. Remote-controlled and autonomous robots enable operators to perform tasks from a safe distance, reducing the risk of exposure to hazardous conditions.

Training and Education:

While robotics technology enhances workplace safety, proper training and education are essential to ensure that human workers understand how to interact with robots safely and effectively. Employers should provide comprehensive training programs that cover topics such as robot operation, maintenance, emergency procedures, and safety protocols. Workers should be familiarized with the capabilities and limitations of robots, as well as the importance of following safety guidelines and using personal protective equipment (PPE) when working with robots.

Conclusion:

In conclusion, robotics technology plays a pivotal role in improving workplace safety by automating hazardous tasks, enabling collaborative operation, providing ergonomic support, and operating in hazardous environments. By leveraging robotics technology, manufacturers can create safer working environments, protect human workers from potential harm, and enhance overall productivity and efficiency. Embracing robotics technology empowers businesses to prioritize safety, comply with regulatory requirements, and foster a culture of safety and well-being in the workplace. As robotics technology continues to evolve, the possibilities for improving workplace safety are limitless, unlocking new opportunities for innovation and advancement across industries.

Enabling Continuous Operation:

Industrial robots enable continuous operation and lights-out manufacturing, allowing production to proceed uninterrupted during non-operating hours. By automating repetitive tasks and minimizing the need for human intervention, robots can operate around the clock, maximizing uptime and throughput. Automated material handling systems, robotic palletizers, and automated guided vehicles (AGVs) facilitate seamless material flow and logistics, further optimizing production efficiency and resource utilization. Additionally, predictive maintenance algorithms and condition monitoring systems enable proactive maintenance and troubleshooting, minimizing downtime and maximizing equipment reliability.

Uninterrupted Production: Robotics’ Role in Enabling Continuous Operation

Introduction:

In the fast-paced world of manufacturing, downtime can translate into significant losses in productivity, revenue, and competitiveness. Ensuring continuous operation of production processes is essential for meeting customer demands, optimizing resource utilization, and maintaining profitability. Industrial robotics have emerged as indispensable assets in enabling continuous operation, facilitating seamless production workflows, and minimizing downtime. This comprehensive exploration delves into the intricacies of robotics’ role in enabling continuous operation, unraveling its capabilities, applications, and transformative impact on manufacturing operations.

The Importance of Continuous Operation:

Continuous operation of production processes is essential for meeting production targets, fulfilling customer orders, and maximizing throughput. Downtime, whether planned or unplanned, can disrupt production schedules, delay order deliveries, and incur costs associated with idle equipment, wasted materials, and missed opportunities. Ensuring continuous operation requires robust and reliable production systems that can operate efficiently and effectively without interruption.

Robotics in Lights-Out Manufacturing:

Lights-out manufacturing, also known as unmanned or autonomous manufacturing, refers to the operation of production processes without human intervention, typically during non-operating hours. Industrial robots play a crucial role in lights-out manufacturing by automating repetitive tasks, handling material flow, and monitoring production processes autonomously. Robots equipped with advanced sensors, actuators, and control systems can operate safely and efficiently in unmanned environments, enabling round-the-clock production with minimal human supervision.

Automated Material Handling Systems:

Material handling is a critical aspect of production processes, encompassing tasks such as loading/unloading, sorting, transporting, and storing materials and workpieces. Industrial robots are deployed in automated material handling systems to facilitate seamless material flow and logistics operations. Robots equipped with specialized end-effectors, conveyors, and palletizers can handle a wide range of materials and products with speed and precision, optimizing throughput and minimizing bottlenecks.

Robotic Palletizing and Packaging:

Robotic palletizing and packaging systems enable manufacturers to automate the final stages of the production process, from packaging finished products to palletizing them for shipping and distribution. Industrial robots equipped with specialized grippers, vision systems, and motion control algorithms can palletize products of varying sizes, shapes, and weights with high speed and accuracy. These systems eliminate the need for manual palletizing, reducing labor costs, and improving efficiency in the packaging and shipping operations.

Predictive Maintenance and Condition Monitoring:

Ensuring continuous operation requires proactive maintenance and monitoring of production equipment to prevent breakdowns and minimize downtime. Robotics technology enables predictive maintenance and condition monitoring of industrial equipment, allowing manufacturers to detect potential issues before they escalate into major failures. Robots equipped with sensors, diagnostic algorithms, and predictive analytics can monitor equipment performance, detect anomalies, and schedule maintenance activities accordingly, ensuring optimal uptime and reliability.

Remote Operation and Monitoring:

Remote operation and monitoring capabilities enable manufacturers to oversee and manage production processes from a centralized location, regardless of geographical distance. Industrial robots equipped with remote control interfaces, telemetry systems, and communication networks enable operators to monitor production status, troubleshoot issues, and adjust production parameters in real-time. Remote operation and monitoring enhance operational visibility, responsiveness, and agility, enabling manufacturers to address production challenges promptly and ensure continuous operation.

Applications Across Industries:

The applications of robotics in enabling continuous operation span across various industries, including automotive, aerospace, electronics, consumer goods, and pharmaceuticals. In automotive manufacturing, robots are used for tasks such as welding, painting, and assembly, enabling round-the-clock production of vehicles. In aerospace manufacturing, robots handle tasks such as composites layup, drilling, and riveting of aircraft structures, ensuring continuous operation of assembly lines. Moreover, robots find applications in electronics manufacturing for tasks such as pick-and-place assembly, soldering, and testing of electronic components, facilitating continuous operation of production facilities.

Conclusion:

In conclusion, the functionality of industrial robotics encompasses a wide range of capabilities and applications that drive efficiency, precision, and innovation in manufacturing. From automating repetitive tasks and handling complex processes to enhancing flexibility, adaptability, and workplace safety, robots play a pivotal role in optimizing production processes and improving competitiveness. Embracing industrial robotics enables manufacturers to achieve operational excellence, meet evolving customer demands, and thrive in the dynamic landscape of modern manufacturing. As robotics technology continues to evolve, the functionality of industrial robots will expand, unlocking new possibilities and driving further advancements in manufacturing efficiency and productivity.