Types of Industrial Robotics (Phase 1)

- Collaborative Robots (Cobots):

Collaborative robots, or cobots, are designed to work alongside humans in shared workspaces, performing tasks that require close collaboration and interaction. These robots are equipped with advanced sensors and safety features that enable safe and intuitive interaction with human operators. Cobots find applications in tasks such as assembly, inspection, packaging, and material handling, enhancing productivity, flexibility, and ergonomics in manufacturing operations. They are widely used in industries such as automotive, aerospace, electronics, and healthcare for tasks such as assembly line tending, quality inspection, and logistics.

Collaborative Robots: Revolutionizing Workplaces with Human-Robot Collaboration

- Introduction:

Collaborative robots, often referred to as cobots, represent a transformative innovation in the field of robotics, enabling seamless interaction and cooperation between humans and machines in shared workspaces. Unlike traditional industrial robots confined to safety cages, collaborative robots are designed to work alongside human operators without the need for physical barriers, facilitating new levels of flexibility, efficiency, and safety in manufacturing and other industries. This comprehensive exploration delves into the intricacies of collaborative robots, their unique features, applications, and transformative impact on workplaces.

- Anatomy of Collaborative Robots:

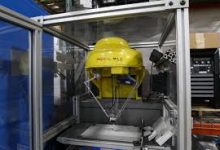

Collaborative robots are typically characterized by their compact size, lightweight design, and advanced safety features, making them well-suited for deployment in various environments. These robots often feature rounded edges, smooth surfaces, and soft covers to minimize the risk of injury in case of accidental contact with humans. Collaborative robots are equipped with advanced sensors and safety systems, including force/torque sensors, proximity sensors, and vision systems, to detect and respond to human presence and avoid collisions. Moreover, collaborative robots may be equipped with intuitive interfaces and programming tools to facilitate easy setup and operation by non-expert users.

Exploring the Anatomy of Collaborative Robots: Design, Components, and Safety Features

Introduction:

Collaborative robots, also known as cobots, represent a significant advancement in robotics technology, designed to work alongside humans in shared workspaces. Unlike traditional industrial robots that require safety cages and barriers, collaborative robots are equipped with advanced safety features and intuitive interfaces, facilitating safe and seamless interaction with human operators. This comprehensive exploration delves into the intricacies of the anatomy of collaborative robots, examining their design, components, and safety features in detail.

- Design of Collaborative Robots:

Collaborative robots are designed with human-robot collaboration in mind, featuring a compact and lightweight design that allows for easy integration into various work environments. Unlike traditional robots, which may have sharp edges and rigid structures, collaborative robots often have rounded edges, smooth surfaces, and soft covers to minimize the risk of injury in case of accidental contact with humans. The design of collaborative robots emphasizes safety, ergonomics, and ease of use, making them suitable for deployment in industries such as manufacturing, healthcare, and logistics where close interaction with humans is required.

- Components of Collaborative Robots:

Collaborative robots consist of various components that enable them to perform tasks autonomously or in collaboration with human operators. These components include:

- Robotic Arm:

The robotic arm is the main structural component of collaborative robots, comprising multiple joints and links that enable precise motion and manipulation of objects. The arm is typically equipped with electric motors, actuators, and sensors for controlling movement and detecting changes in the environment.

- End-Effector:

The end-effector, or tooling, is the component mounted at the end of the robotic arm that interacts with objects in the workspace. End-effectors may include grippers, suction cups, or specialized tools designed for specific tasks such as picking, placing, or manipulating objects.

- Sensors:

Collaborative robots are equipped with advanced sensors that enable them to perceive their environment and detect the presence of humans and obstacles. These sensors may include proximity sensors, force/torque sensors, vision systems, and depth cameras, allowing the robot to navigate safely and interact with its surroundings.

- Safety Features:

Collaborative robots are equipped with a range of safety features to ensure safe operation in proximity to human operators. These features may include force limiting, speed monitoring, collision detection, and hand guiding, allowing the robot to adjust its behavior in real-time to avoid accidents and injuries.

- Control System:

The control system is the brain of the collaborative robot, responsible for processing sensor data, executing tasks, and generating commands for actuators. The control system may include microcontrollers, programmable logic controllers (PLCs), and software algorithms for motion planning, path optimization, and task execution.

Safety Features of Collaborative Robots:

Safety is a paramount concern in the design and operation of collaborative robots, given their close interaction with human operators. Collaborative robots are equipped with advanced safety features that enable them to operate safely in shared workspaces, including:

- Force Limiting:

Collaborative robots are designed to limit the amount of force exerted on objects and humans in case of accidental contact. Force limiting mechanisms, such as compliant joints and torque sensors, allow the robot to detect and react to changes in external forces, reducing the risk of injury.

- Speed Monitoring:

Collaborative robots are equipped with speed monitoring systems that regulate the robot’s speed based on the proximity of humans and other obstacles. By monitoring the robot’s speed and adjusting it dynamically, these systems ensure safe operation in shared workspaces.

- Collision Detection:

Collaborative robots employ collision detection algorithms and sensors to detect the presence of humans and obstacles in their path. If a collision is detected, the robot can stop or slow down to avoid accidents and injuries.

- Hand Guiding:

Some collaborative robots feature hand guiding capabilities that allow human operators to teach the robot new tasks by physically guiding its movements. Hand guiding enables intuitive and flexible programming of the robot, facilitating collaboration between humans and machines.

- Conclusion:

In conclusion, the anatomy of collaborative robots reflects a careful balance between functionality, safety, and ease of use. By incorporating advanced sensors, safety features, and intuitive interfaces, collaborative robots enable safe and seamless interaction with human operators in shared workspaces. As technology continues to advance, collaborative robots will play an increasingly important role in various industries, driving efficiency, productivity, and innovation in manufacturing, healthcare, and beyond.

- Modes of Collaboration:

Collaborative robots support various modes of interaction and collaboration with human operators, depending on the specific task requirements and safety considerations. In some scenarios, collaborative robots operate in close proximity to humans, performing tasks such as assembly, inspection, and packaging alongside human workers on shared workbenches or assembly lines. These robots are equipped with advanced safety features such as force limiting, speed monitoring, and collision detection to ensure safe operation in proximity to humans. In other scenarios, collaborative robots operate in a hand-in-hand mode, where human operators guide the robot’s movements manually using haptic interfaces or teach pendant devices. This mode of collaboration allows for intuitive and flexible control of the robot’s motion, enabling precise and dexterous manipulation of objects in complex tasks such as polishing, deburring, and assembly.

- Applications in Manufacturing:

Collaborative robots find diverse applications across various manufacturing industries, owing to their flexibility, adaptability, and safety. In automotive manufacturing, collaborative robots are used for tasks such as assembly line tending, quality inspection, and machine tending, where they work alongside human workers to improve productivity and efficiency. In electronics manufacturing, collaborative robots are employed for tasks such as soldering, pick-and-place assembly, and testing of electronic components, enabling manufacturers to meet the demand for high-mix, low-volume production with greater agility and responsiveness. Moreover, collaborative robots find applications in industries such as aerospace, consumer goods, and pharmaceuticals for tasks such as packaging, material handling, and logistics, where they enhance productivity, flexibility, and ergonomics in manufacturing operations.

Revolutionizing Manufacturing: The Diverse Applications of Robotics

- Introduction:

The integration of robotics into manufacturing processes has revolutionized industries worldwide, offering unparalleled levels of efficiency, precision, and flexibility. From automotive assembly lines to pharmaceutical production facilities, robotics plays a crucial role in streamlining operations, enhancing quality, and driving innovation. This comprehensive exploration delves into the diverse applications of robotics in manufacturing, highlighting their transformative impact across various sectors.

- Assembly and Production:

Robots are widely utilized in assembly and production processes across diverse industries, including automotive, electronics, and consumer goods. In automotive manufacturing, robots perform tasks such as welding, painting, and assembly of vehicle components with unmatched speed and precision. Automated assembly lines enable continuous production, minimizing downtime and optimizing throughput. Similarly, in electronics manufacturing, robots are used for soldering, pick-and-place assembly, and testing of electronic components, ensuring consistency and quality in production. Moreover, robots are employed in consumer goods manufacturing for tasks such as packaging, labeling, and inspection, improving efficiency and reducing labor costs.

- Material Handling and Logistics:

Material handling and logistics represent critical aspects of manufacturing operations, and robots play a pivotal role in optimizing these processes. Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) are used for transporting materials, components, and finished products within factories and warehouses. These robots navigate autonomously using sensors and onboard navigation systems, optimizing workflow and minimizing manual labor. Additionally, robotic arms and grippers are employed for palletizing, sorting, and loading/unloading tasks, enhancing efficiency and throughput in distribution centers and fulfillment operations.

- Machining and CNC Automation:

Robotics has transformed the field of machining and computer numerical control (CNC) automation, enabling high-precision and high-speed machining operations. Computer-controlled robotic arms equipped with cutting tools, such as milling cutters and drills, perform complex machining tasks with unparalleled accuracy and repeatability. CNC robots are used in industries such as aerospace, medical device manufacturing, and precision engineering for machining components with intricate geometries and tight tolerances. Robotic machining cells enable lights-out manufacturing, allowing production to continue uninterrupted during non-operating hours.

- Quality Inspection and Testing:

Quality inspection and testing are integral parts of manufacturing processes, and robotics play a crucial role in ensuring product quality and compliance with standards. Vision systems, equipped with cameras and image processing algorithms, are used for inspecting products for defects, dimensional accuracy, and surface finish. Robots equipped with sensors and measurement tools perform non-destructive testing (NDT) and metrology tasks, verifying the integrity and performance of components. Automated inspection systems enhance efficiency and consistency in quality control processes, reducing the risk of defects and recalls.

- Additive Manufacturing and 3D Printing:

Additive manufacturing, commonly known as 3D printing, has emerged as a disruptive technology in manufacturing, and robotics are at the forefront of this innovation. Robotic arms equipped with extrusion, deposition, or powder bed fusion technologies build complex geometries layer by layer, enabling rapid prototyping, tooling production, and customized part manufacturing. Additive manufacturing robots are used in industries such as aerospace, automotive, and healthcare for producing lightweight components, spare parts, and patient-specific medical devices. The flexibility and scalability of robotic 3D printing enable agile and cost-effective manufacturing solutions.

- Collaborative and Flexible Automation:

Collaborative robots, or cobots, are redefining the landscape of manufacturing by enabling human-robot collaboration in shared workspaces. Cobots work alongside human operators, performing tasks that require close interaction and cooperation. These robots are equipped with advanced safety features, such as force limiting and collision detection, ensuring safe operation in proximity to humans. Cobots find applications in tasks such as assembly, inspection, and packaging, enhancing productivity, flexibility, and ergonomics in manufacturing operations. Moreover, flexible automation solutions, enabled by robotic systems and smart manufacturing technologies, allow manufacturers to adapt to changing production requirements and market demands rapidly.

- Conclusion:

In conclusion, the applications of robotics in manufacturing are vast and diverse, encompassing assembly, material handling, machining, quality inspection, additive manufacturing, and collaborative automation. Robotics technologies continue to evolve, driving innovation and transformation in industries worldwide. As manufacturers seek to increase efficiency, improve quality, and respond to market dynamics, robotics will play an increasingly important role in shaping the future of manufacturing. Embracing robotics offers opportunities for businesses to achieve operational excellence, drive sustainable growth, and maintain a competitive edge in the global marketplace.

- Advancements in Technology:

Collaborative robots have benefited from advancements in technology, including improvements in materials, actuators, sensors, and control systems. Lightweight materials such as aluminum and carbon fiber have enabled the development of more agile and energy-efficient robots with higher payload capacities. High-performance electric motors, servo drives, and harmonic gearboxes provide precise and reliable motion control, enhancing robot performance and productivity. Advanced sensors, such as force/torque sensors, proximity sensors, and vision systems, enable collaborative robots to perceive their environment and respond to changes in real-time, ensuring safe and accurate operation in proximity to human workers. Moreover, advancements in control algorithms and software enable collaborative robots to perform complex tasks with speed, accuracy, and adaptability, driving efficiency and innovation in manufacturing processes.

Exploring the Cutting-Edge Advancements in Robotics Technology

- Introduction:

The field of robotics has witnessed remarkable advancements in recent years, propelled by breakthroughs in materials science, artificial intelligence, sensing technologies, and more. These advancements have revolutionized the capabilities and applications of robots across various industries, from manufacturing and healthcare to agriculture and space exploration. This comprehensive exploration delves into the cutting-edge advancements in robotics technology, highlighting their transformative impact and potential future developments.

- Artificial Intelligence and Machine Learning:

Artificial intelligence (AI) and machine learning (ML) are at the forefront of robotics innovation, enabling robots to perceive, learn, and adapt to dynamic environments. AI algorithms empower robots with advanced perception capabilities, allowing them to interpret sensor data, recognize objects, and make intelligent decisions in real-time. Machine learning algorithms enable robots to learn from experience and improve their performance over time through iterative training and feedback. These capabilities have led to the development of autonomous robots capable of complex tasks such as navigation, manipulation, and decision-making in unstructured environments.

- Sensing and Perception Technologies:

Advancements in sensing and perception technologies have enhanced the ability of robots to interact with their surroundings and perform tasks with precision and accuracy. Vision systems equipped with high-resolution cameras, depth sensors, and machine vision algorithms enable robots to perceive and recognize objects, obstacles, and environments in three dimensions. Lidar and radar sensors provide robots with 3D spatial awareness and enable obstacle detection and avoidance in dynamic environments. Additionally, tactile sensors and force/torque sensors enable robots to sense and respond to physical contact with objects and humans, facilitating tasks such as manipulation, grasping, and collaborative operation.

- Soft Robotics and Flexible Materials:

Soft robotics is an emerging field that focuses on the design and development of robots using flexible materials and structures inspired by biological systems. Soft robots exhibit unique capabilities such as compliance, adaptability, and resilience, making them well-suited for tasks in unstructured environments and human-robot interaction. Advances in materials science, including elastomers, polymers, and shape-memory alloys, have enabled the fabrication of soft actuators, sensors, and grippers that mimic the flexibility and dexterity of human muscles and tissues. Soft robotics holds promise for applications in fields such as healthcare, rehabilitation, and search and rescue, where traditional rigid robots may be unsuitable.

- Swarm Robotics and Collective Behavior:

Swarm robotics is an interdisciplinary field that studies the coordination and cooperation of multiple robots working together to achieve common goals. Inspired by the collective behavior of social insects such as ants and bees, swarm robotics aims to design decentralized, self-organizing systems capable of robust and adaptive behavior in complex environments. Swarm robots communicate and coordinate their actions through local interactions and simple rules, enabling them to perform tasks such as exploration, mapping, and surveillance in unknown or hazardous environments. Swarm robotics has applications in fields such as disaster response, environmental monitoring, and distributed sensing, where large-scale coordination and cooperation are required.

- Human-Robot Interaction and Collaboration:

Advancements in human-robot interaction (HRI) technologies have facilitated seamless collaboration and cooperation between humans and robots in shared workspaces. Collaborative robots, or cobots, are designed to work alongside humans, performing tasks that require close interaction and cooperation. These robots are equipped with advanced safety features, intuitive interfaces, and adaptive control algorithms that enable safe and efficient collaboration with human operators. Moreover, advances in augmented reality (AR) and virtual reality (VR) technologies enable immersive teleoperation and remote control of robots, allowing human operators to interact with robots from a distance and in virtual environments.

- Autonomous Navigation and Mobility:

Autonomous navigation and mobility are critical capabilities for robots operating in dynamic and unpredictable environments. Advances in robotics have led to the development of autonomous navigation systems that enable robots to perceive their surroundings, plan optimal paths, and navigate autonomously in complex environments such as indoor spaces, outdoor terrains, and aerial environments. Localization techniques such as simultaneous localization and mapping (SLAM) enable robots to build maps of their environment and estimate their position and orientation in real-time. Mobile robots equipped with sensors, actuators, and onboard computing systems navigate autonomously using algorithms such as path planning, obstacle avoidance, and trajectory optimization.

- Conclusion:

In conclusion, the advancements in robotics technology are driving innovation and transformation across various industries, enabling robots to perform increasingly complex tasks with autonomy, intelligence, and adaptability. From artificial intelligence and machine learning to sensing and perception technologies, soft robotics, swarm robotics, human-robot interaction, and autonomous navigation, robotics technology continues to evolve at a rapid pace. As researchers and engineers push the boundaries of innovation, the future of robotics holds promise for unprecedented capabilities and applications, shaping the way we live, work, and interact with machines in the digital age.

- Collaborative Work Environments:

Collaborative robots are transforming work environments by fostering collaboration and cooperation between human workers and machines. In collaborative work environments, human operators and robots work together seamlessly, leveraging their respective strengths to perform tasks more efficiently and effectively. Collaborative robots assist human workers by handling repetitive, tedious, or dangerous tasks, allowing humans to focus on more value-added activities that require creativity, problem-solving, and decision-making skills. Moreover, collaborative robots enhance workplace safety by reducing the risk of accidents and injuries associated with manual labor and heavy machinery. By promoting human-robot collaboration, collaborative robots empower organizations to achieve higher levels of productivity, quality, and innovation, while also improving employee satisfaction and well-being.

Embracing Collaborative Work Environments: The Role of Robotics in Human-Robot Collaboration

Introduction:

In the ever-evolving landscape of manufacturing and beyond, collaborative work environments are becoming increasingly prevalent. These environments, where humans and robots work together seamlessly, offer a multitude of benefits including increased productivity, improved safety, and enhanced flexibility. Robotics plays a pivotal role in enabling and optimizing human-robot collaboration, revolutionizing industries ranging from manufacturing to healthcare and beyond. This comprehensive exploration delves into the intricacies of collaborative work environments, highlighting the role of robotics in fostering cooperation and synergy between humans and machines.

Understanding Collaborative Work Environments:

Collaborative work environments entail the integration of human and robotic resources in shared workspaces, where they collaborate to achieve common goals. Unlike traditional manufacturing setups where robots are isolated behind safety cages, collaborative work environments facilitate direct interaction and cooperation between humans and robots. These environments promote a symbiotic relationship, where each party leverages its unique strengths and capabilities to enhance overall productivity and efficiency.

The Role of Robotics in Collaboration:

Robotics technology plays a crucial role in enabling and enhancing collaboration within shared workspaces. Collaborative robots, or cobots, are specifically designed to work alongside humans, performing tasks that require close interaction and cooperation. Unlike traditional industrial robots, cobots are equipped with advanced safety features such as force limiting, speed monitoring, and collision detection, ensuring safe operation in proximity to humans. Moreover, cobots are characterized by their flexibility, adaptability, and ease of use, making them suitable for a wide range of applications in manufacturing, healthcare, logistics, and beyond.

- Applications in Manufacturing:

In manufacturing, collaborative work environments have revolutionized production processes, enabling manufacturers to achieve higher levels of efficiency, flexibility, and quality. Collaborative robots are employed for tasks such as assembly, inspection, packaging, and material handling, working alongside human operators on shared workstations or assembly lines. These robots enhance productivity by automating repetitive and physically demanding tasks, allowing human workers to focus on more value-added activities such as problem-solving, quality control, and process optimization.

- Applications in Healthcare:

In healthcare, collaborative work environments are transforming patient care and medical procedures, enhancing efficiency, safety, and patient outcomes. Collaborative robots are used in surgical settings for tasks such as instrument delivery, tissue manipulation, and suturing, assisting surgeons in complex procedures and minimizing the risk of human error. Moreover, collaborative robots are employed in rehabilitation and therapy settings to assist patients with mobility training, exercises, and activities of daily living, facilitating recovery and improving quality of life.

- Challenges and Considerations:

While collaborative work environments offer numerous benefits, they also present challenges and considerations that must be addressed. Safety is paramount in collaborative environments, and robust safety protocols and risk assessments are essential to ensure the well-being of human operators and the safe operation of robots. Moreover, effective communication and coordination between humans and robots are critical for successful collaboration, requiring intuitive interfaces and adaptive control algorithms. Additionally, workforce training and education are essential to equip human operators with the skills and knowledge necessary to interact and collaborate effectively with robots in shared workspaces.

- Future Directions:

Looking ahead, the future of collaborative work environments holds promise for further innovation and advancement. As robotics technology continues to evolve, collaborative robots will become more intelligent, adaptable, and autonomous, enabling seamless cooperation and synergy between humans and machines. Moreover, advancements in artificial intelligence, machine learning, and sensing technologies will enhance the perception, decision-making, and interaction capabilities of robots, further expanding the possibilities for collaboration in diverse industries and applications.

Conclusion:

In conclusion, collaborative work environments represent a paradigm shift in the way humans and robots interact and cooperate in shared spaces. Enabled by robotics technology, these environments offer unprecedented levels of productivity, safety, and flexibility, driving innovation and transformation across industries. Embracing collaborative work environments presents opportunities for businesses to achieve operational excellence, enhance competitiveness, and adapt to the evolving demands of the digital age. As robotics technology continues to evolve, collaborative work environments will play an increasingly important role in shaping the future of work and production.

- Conclusion:

In conclusion, collaborative robots represent a paradigm shift in industrial automation, enabling seamless interaction and cooperation between humans and machines in shared workspaces. With their advanced safety features, intuitive interfaces, and flexible programming capabilities, collaborative robots are revolutionizing workplaces across various industries, from automotive and electronics to aerospace and pharmaceuticals. By fostering human-robot collaboration, collaborative robots enhance productivity, flexibility, and safety in manufacturing operations, while also empowering organizations to adapt to changing market demands and achieve sustainable growth in the digital age. As technology continues to advance and evolve, collaborative robots will play an increasingly important role in shaping the future of work, driving innovation and transformation in workplaces worldwide.